This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

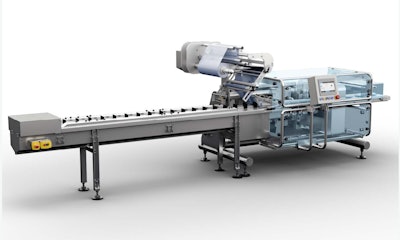

BW Flexible Systems, a global provider of flexible packaging solutions for food and non-food products, introduces its flow wrapper portfolio in Booth #616 at PACK EXPO East, held March 18 to 20 in Philadelphia. Renowned for its quality and robustness, the Hayssen hand-fed flow wrapper provides a simple and user-friendly experience for operators, with innovative features that allow for easy changeovers and automated adjustments to maximize uptime. The Hayssen R300 is ideal for flow wrapping baked goods like single cookies, brownies, Danishes, croissants, small pies, whoopie pies, crispy rice treats and more.

"The Hayssen R300 was designed with first-time machine owners and operators in mind," said BW Flexible Systems' Product Line Leader Brantley Turner. "It provides a more user-friendly experience compared to other hand-fed flow wrappers with features that make this machine easy to learn, set up and use by any operator."

Its new design aims to increase ease of use, minimize chances of setup error and improve ergonomics for operators. With operator turnover rates on the rise, its more intuitive human-machine interface (HMI) design allows new operators to learn the system and onboard faster. On top of the user-friendly HMI, the Hayssen R300 has an ultra-low roll height, which increases operator accessibility.

To maximize uptime, the Hayssen R300 provides simple features to automatically eliminate jaw jams. Unlike most other flow wrappers, the Hayssen R300 has clear guards and an open design to provide better visibility into the long seam unit for safe and timely troubleshooting. Other features that help operators respond to faults faster include an additional control panel at the operator’s point of use and large LED lights to indicate the machine’s status at a distance.

In addition to its usability, it also offers hygienic design features that make it easy to clean. The infeed incorporates an openchannel stainless steel design and sloped pans underneath, making wiping down or rinsing fast and effortless. The Hayssen R300 is beginner friendly, while also offering options for upgrades and automation as needed. The adjustable folding box can suit a wide range of SKUs to accommodate future line expansion or changes.

PACK EXPO East attendees will have the opportunity to explore the complete range of Hayssen flow wrappers, including the innovative features of the Hayssen R300, and will get a chance to engage with our machine design and application experts. Additionally, Hayssen’s vertical form-fill-seal team also will be present at the Expo.