With the emphasis on new machinery introductions, trade shows like Pack Expo are always a fascinating showcase for new developments. At the latest Pack Expo iteration in September in Las Vegas and amidst the usual whizz-bang of machinery capabilities, I came across two different takes on machinery documentation that merit mention.

These were two companies, two ideas, two diverse approaches—one high tech, the other low tech—but one purpose: To make the interaction of man (or woman) and machine better, especially for the inevitable times of trouble. Both bring utility right to the packaging machine, and both can make a timely difference on the plant floor.

Before getting into the details, I asked John Henry, the Changeover Wizard of Changeover Inc., what he thought about suppliers addressing machinery documentation accessibility.

Good idea, few followers

"I would say that any documentation that a manufacturer provides for training is welcome, regardless of how it is supplied," says Henry. "My experience with operation manuals over the years has not been good. PMMI [Packaging Machinery Manufacturers Institute] has some good guidelines that I have used to write manuals for clients, both machine builders and end users. The problem is that few builders seem to be following them."

Perhaps that's starting to change, at least as is evident in the following two examples on different ends of the complexity spectrum.

Taylor's high-tech, on-demand training

On-demand training highlighted at the booth of Taylor Products div. of Magnum Systems. The company offers a computer-based training option that debuts with the new V-5100 vertical form/fill/seal baler (see image one, of screen capture). The PC-based On Demand Training module was custom-developed for the V-5100 baler by Halo Training Ltd. of the United Kingdom.

It's more than an electronic version of the machine's operating manual, according to Taylor Products vice president of sales and marketing Gary Saunders. Operators can use the interactive system to train, gain better understanding of machine functions and options, and also to troubleshoot, he says. It includes animations and video clips such as showing an operator how to thread the film web, Saunders points out. The program is accessible through an industrial PC or a laptop. Taylor Products offers it as an add-on priced at under $2ꯠ. Saunders says it can pay for itself if it prevents one weekend service call.

"It's often the simplest problems that can lead to downtime," Saunders explains, "and it's often that the most technically proficient plant person may not be available when that happens. ODT is always available."

Customers have asked for a feature like this, and Taylor Products wanted to gauge interest by introducing this feature at the PELV show, Saunders says: "We received a tremendous response at the show, and we're planning to incorporate ODT in other equipment in the future."

The program is in English, though Saunders says it can be made available in any language.

"PC-based control systems are becoming more and more common," comments Henry. "If you have a PC already on the machine and you have the documentation in electronic format, it seems like a no-brainer to combine the two. Not enough companies do this. Pictures and video can also be easily incorporated."

Henry does have one concern: Security.

"One concern with electronic systems is ensuring the integrity of the manual," he says. "You need to prevent anyone from making unauthorized changes or additions. This added security is not hard to do, but it must be considered."

Taylor Products' Saunders says its system is a secure, read-only format.

Loveshaw's low-tech assist

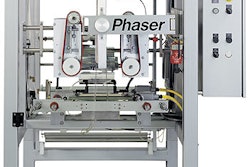

At the other end of the spectrum is the simple, convenient, and economical tack taken by Loveshaw. The company was highlighting at PELV its latest semi-automatic machine, the CF-5 Case Former, on which a laminated operating manual was affixed via pressure-sensitive adhesive right onto the frame. So rather than loose in a drawer or who knows where or lost, it's available right at the point of use where it's needed most (see image two).

"Mounting the instructions like this is an excellent idea," says Henry. "I have seen this used in a number of plants for internally generated changeover, operation and maintenance Standard Operating Procedures, but I don't recall having seen any builders putting it on the machinery."

Loveshaw marketing manager Valerie Burke says the "flip chart" was a customer-inspired idea that they've used for several years: "The customer wanted the instructions to be so straightforward that a 'Joe' off the street could read it and run the machine." Maybe that could be a Jose: Within a year of the debut, the 8- to 10-page manual was made bilingual with Spanish. The flip chart contains set-up instructions and a troubleshooting guide.

"We will continue to use the flip-chart manual going forward on all new machines," Burke states.

The Changeover Wizard is impressed by these two diverse approaches.

"A second problem with machine manuals is accessibility and both these approaches seem excellent," sums Henry.