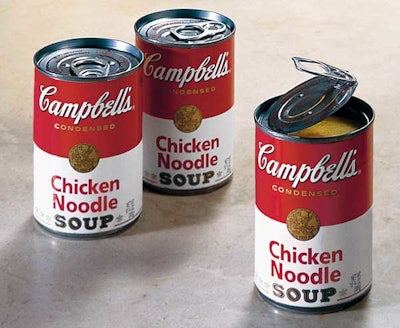

“At Campbell Soup, we are very focused on the continuous improvement of our products and production processes,” says Steve Demuri, Campbell Soup research program manager. “The Cognex machine vision system gives us another level of safety, knowing that every single can is being inspected. Using Cognex systems, we can be assured that the right product is in the right can.”

In its packaging lines, the vision system will first verify the ink-jet-printed product code marked on the bottom of each steel can before the label is applied. The code contains production information specific to each type of soup. Only after the code is read and verified will the label be applied. The MVS-8500 is capable of checking the codes while the cans are moving at the maximum production rate to virtually eliminate the chance of product mislabeling.

“Reading codes in Campbell’s production environment is very different from reading codes on the surfaces of semiconductor wafers in clean rooms, which has historically been one of our largest applications,” says Robert J. Shillman, Cognex chief executive officer and chairman. “I’ve always predicted that Cognex’s vision systems would be used to inspect everything from ‘soup to nuts,’ and now we’re halfway there!”