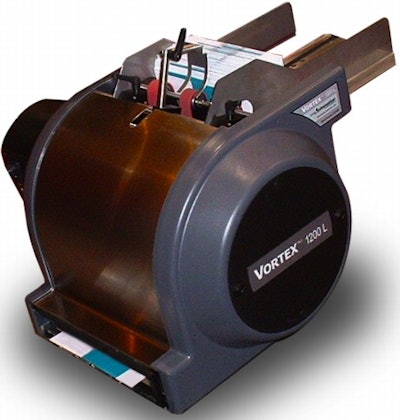

Using 7 different auto-adjusting features, the Vortex eliminates time-consuming and skill-dependent operator setup and testing for product changeover. Unlike traditional friction feeders that use high friction forces to pull product off the bottom of a high-pressure product stack, the Vortex uses a patent-pending, low-sheer feeding technique that gently lifts the product into the feed and separation area. This means that the Vortex is not sensitive to the amount of product in the stack. Technique results in high reliability by eliminating feed errors associated with material thickness variations. Ideal for collating with perpendicular feeds. Feeds traditional products as well as flat, rigid items. Full-featured servo version starts at $12꽤, about half the cost of competing models, according to the company.