Cardinal’s Pharmaceutical Technologies and Services (PTS) operations were recently divested and acquired by The Blackstone Group (www.blackstone.com). This information was shared by Renard Jackson, formerly VP/GM Global Packaging Services of Cardinal Health, Dublin, OH, and now with PTS. Key aspects:

• Single infrastructure ultra-high frequency technology for traceability at the item, case, and pallet level.

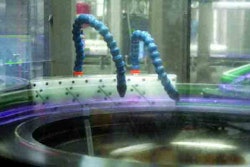

• Encoding done at production speeds using Gen 2 Class 1 tags including a new antenna form factor for pharmaceuticals.

• Used SNDC-96-bit data encoding at the item and case level. The overall system showed the capability to capture and store it as well as SSCC (Serial Shipper Container Code) format used for pallets.

Conclusions:

• RFID tags can be successfully inlaid under existing FDA-approved pharmaceutical label stock.

• Packaging lines can run at validated speeds while encoding and verifying RFID tag application.

• A single frequency (UHF) has the potential to work at critical points from pharmaceutical packaging to pharmacy receipt. Also, no tag failures were encountered in any stage of the pilot.

• Item-level reads are impossible when cases are stacked on a pallet.

• Unit read rates within mixed totes are highly reliable (>90%), but have not achieved six sigma quality.

• 100% read rates of case tags on as full pallet are potentially obtainable, but further testing is needed.

• Case read rates on a moving conveyor at receiving had read rates in excess of 99%.

RFID technology is feasible for “tracking and tracing” item-level drugs in the pharmaceutical supply chain provided the following conditions and processes are met:

• Item-level tracking reads are limited to individual each and case- read processes with conditions of an ideal/consistent state.

• Inference (aka child-parent association) is allowed to become an acceptable practice in the normal distribution process schemes, bottle-case, case-pallet, item-tote.

• Bar code technology is used in a redundant/complementary strategy to allow “Track & Trace” in areas of privacy concerns, biologic product distribution and RFID tag failure.

• Implementation is measured and managed in a manner consistent with the technologies capability, the compliance risk and the financial impact on individual stakeholders.

• Higher levels of collaboration are initiated among stakeholders to identify opportunities in the supply chain to significantly improve efficiencies and reduce costs.