Portability, tactility and “drinkability” are the primary consumer benefits of a new bottle and closure combination for single-serve milks marketed by Country Fresh, Inc. In late August, the Grand Rapids, MI-based dairy began selling vitamin- and calcium-fortified kidsmilk™ in what’s called the Squish-Pak!® container. That follows the recent rollout of Milk-It!® milks in the identical bottle/closure.

Country Fresh is part of Suiza Foods’ Midwest Region. The dairy began test-marketing Milk-It! in the container in ’98. The company continues to expand the product’s distribution. Progressive Plastics (Cleveland, OH) injection blow-molds the “soft” low-density polyethylene bottle.

The soft, squeezable tactility is achieved through molding on a Uniloy Milacron (Manchester, MI) machine. During the process, the machine molds bottles at the thinnest wall thickness that will still deliver enough rigidity to withstand distribution rigors.

‘Sipper’ closure

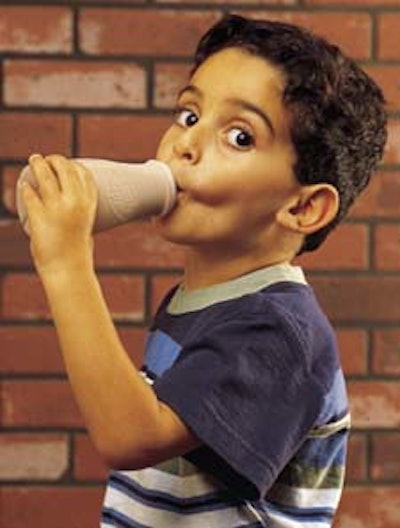

Made to fit a child’s hand, the bottle’s softness allows kids to easily squeeze the 8 oz of milk through a spout. It’s called a “sipper protrusion” and is a two-piece, injection-molded LDPE closure supplied by Portola Packaging (San Jose, CA). Before drinking, kids remove a tamper-evident “zip strip” to open the pack. The zip strip safety band stays attached to the top piece of the closure during opening. Once the top portion of the closure is removed, the sipper protrusion is revealed.

The protrusion is part of a second plug-like part of the closure that fits into the container’s neck. Country Fresh promotional literature describes the closure as a “tamper-evident, spill-resistant, reclosable cap.” The top piece can be snapped back onto the sipper piece to provide reclosability.

Six bottles are sold in a 22-pt paperboard carton from Artistic Carton (Elgin, IL). A graphic on the bottom of the die-cut carrier instructs users how to open and reclose the bottle. The carton sports eye-catching graphics that vary for the two brands. Cartons for both brands provide shelf appeal, and two die-cut finger grips on the top make it easy to pick up and carry the pack. Milk-It! is sold in three 2% varieties: Chocolate Smash™, Milk Blast™ and as of July, Strawberry Dash™. Six-packs retail for $2.99 in select Michigan and Indiana stores.

Shelf life is 20 days refrigerated for both Milk-It! and kidsmilk. The latter brand is available only in chocolate at this time, retailing for $3.09 at test markets in Michigan. Marketing representative Rosalyn Risdon says kidsmilk “will expand to selected Midwest markets after the test market.”

Previously, kidsmilk was sold in 57-oz and 114-oz rigid high-density PE containers. These Smart Jug™ containers are blow-molded by Consolidated Container (Irving, TX). According to Country Fresh, Suiza owns the Smart Jug trademark. The “smart” refers to its consumer-friendly features: a pour spout located conveniently at the “front” of the container rather than in its center, a larger handle with finger grips and grooves at the bottle’s base that make it easier to tilt the bottle while pouring.

While these larger sizes are still available, the success of Milk-It! in single-serve bottles convinced the dairy to use them for kidsmilk as well.

Risdon wouldn’t comment on bottle costs but did say that “it seems economically reasonable” that larger-volume purchases of the Squish-Pak! bottles to accommodate both brands would yield a price advantage for Country Fresh. A second brand also means the firm utilizes more of the filling line’s capacity.

The package evolves

“We began test-marketing the Milk-It! product in about 100 stores in western Michigan in the fall of 1998,” recalls Country Fresh president Delton Parks. The dairy says it acquired the rights to use the container and the Squish-Pak! and Milk-It! brand names from Thompson Beverage Systems, the firm that invented and patented the bottle. That was in late ’95/early ’96 (see Packaging World, Dec. ’95, p. 25, or packworld.com/go/milkit).

Country Fresh’s Parks says Milk-It! is now in nearly 400 Midwest stores. “Our goal is to push it into 600 Midwest supermarkets,” he says. The company is also planning to roll the milks into markets nationwide, adding equipment to other Suiza plants to bottle the beverage.

Currently, the milk is filled at Suiza’s C.F. Burger Div. dairy in New Paris, IN. That plant uses a modified Federal (Milwaukee, WI) filler and capper, which fill and cap at speeds of around 150/min.

“We modified feed chutes to handle the cap,” says Mike Parks, the company’s purchasing manager. “The filler can run at 200 a minute, but we don’t run it that fast now. It’s a straight-line filling operation, and I’d estimate that by [later this year], we’ll be in the process of putting in an unscrambler at the beginning of the line,” which he says will allow the line to run at the filler’s 200 bpm capacity.

After filling and capping, bottles are coded with plant identification and “best-if-sold-by” date, applied by a Videojet ink-jet coder from Marconi Data Systems (Wood Dale, IL). Coded bottles proceed to an Adco (Sanger, CA) cartoner. “We bought that machine in ’98,” Mike Parks explains. “It wraps the paperboard blanks around the bottles. Three locking tabs on the bottom are closed into matching slots” to close the carton. Another Videojet unit codes the carton. Afterward, cartons are manually packed into a corrugated case.

“We’ll also be automating that shortly,” says Mike Parks. While it’s too early to determine how well kidsmilk is faring, “the market has shown an excellent reception to Milk-It!,” concludes Delton Parks, “and we’re also looking at using this bottle for fluoridated water and juices.”