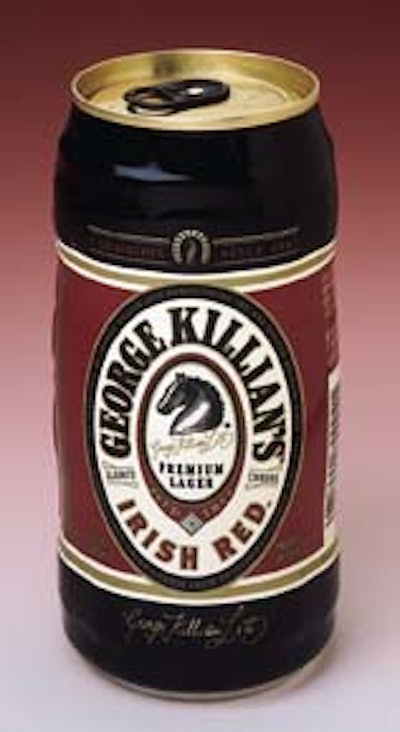

If looks count in packaging, then Coors, Golden, CO, scores twice for Killian’s® Pub Barrel™ introduced earlier this year (see Packaging World, May ’00, page 53). The product possesses a pair of attention-getting touches: a printed shrink-film label that enwraps a 12-oz barrel-shaped aluminum can. The full-body shrink label hugs the can’s contours to reveal its barrel-like ridges. Killian’s is a rare example of full-body shrink labeling on a contour can.

Not only do these features work in tandem, but they also are done in tandem on the production line. The cans are shaped and labeled on a reconfigured production line at Valley Metal’s can manufacturing plant in Golden. Valley is a joint venture between Coors and Rexam Beverage Cans America (Chicago, IL), formerly American National Can Co., the latter of which provides the can-shaping equipment.

After the 12-oz aluminum can bodies are shaped, the shrink film label is applied by a BH8000S labeler and BH700 Endura® shrink tunnel from B&H Labeling Systems (Ceres, CA).

By late December ’99, the first Killian’s pub barrels for commercial sale were rolling off the line, says Frank Shriver, Coors senior packaging development engineer. The plan was to have the product available for retail sale by St. Patrick’s Day, March 17, he adds.

A 250 cpm pace

The cans roll off the can-shaping and labeling line at 250 cans/min. At the start of the U-shape line, cans are automatically depalletized before they are conveyed to ANC’s Swiss-made can-shaping equipment. The shaper forms the regular straight-wall aluminum cans into the barrel shape. Shriver says the cans, manufactured by Valley Metal, are made of heavier-than-usual gauge aluminum. This helps the shaped cans maintain compression strength for shipment.

The cans are printed by Valley with a black ring near the top so that when labeled, the small amount of can showing beneath the label at the top blends in seamlessly with the black part of the label rather than as shiny metal ring.

Shaped cans are checked for any splitting or other leaks or defects by a Reynolds rotary testing machine. It is located about 15’ downstream of the shaper. The open can end is covered by a seal while an intense light shines on the can exterior. A photo detector checks for any incoming light that would indicate a pinhole or split.

Defective cans are rejected from the line, while intact cans are conveyed onward to the labeler located on a mezzanine about 50’ away.

The roll-fed labeler uses Aerowrap® film from Salem Label (Salem, OH). Killian’s label is a 2.2-mil lamination of clear printed oriented polypropylene on the outside and an opaque white OPP inner layer. The clear film is reverse-printed flexographically in five colors. The OPP substrates are ROSO (“roll-on, shrink on”) films supplied by ExxonMobil’s Film Business (Macedon, NY). One of the main reasons Coors selected OPP film was that it believed the film to be more recyclable than alternative substrates such as polyvinyl chloride, Shriver explains.

Drum roll-on

At the entrance to the labeler, the cans are metered by feed screw into the infeed starwheel that rotates the cans around toward a vacuum drum that transfers the label onto the can.

After a photo eye detects the presence of the can, the roll-fed label is advanced and is cut in register. This is via B&H’s patented Computerized Registration System (CRS™) that automatically adjusts to variations in label length. The CRS uses a photo-eye sensor that monitors the registration marks on the film and adjusts the label feed to ensure the labels are precisely cut every time.

The label is transferred from the roll onto the vacuum drum where it is held print side inward. While it is on the drum, hot melt adhesive is applied by a glue wheel to the label’s front leading edge and then to the trailing edge. The adhesive is applied via engravings on the wheel, which operates against scraper bars that maintain a very thin layer of the adhesive, PW is told.

Shriver says the adhesive on the label’s leading edge is spot-applied in areas corresponding to the three raised areas of the can: top, middle and bottom. For labeling of straightwall cans, the adhesive pattern is applied as a continuous strip. An example is the Grid Iron Warriors cans promoted during the fall football season, which can be seen running in the photos. The Warriors line exemplifies the use of the technology for promotional and other short-term efforts.

As it releases spinning from the star, the can catches the label’s front edge via the adhesive. In conjunction with an air blow assist, this transfers the label fully from the drum to the can.

The vertical placement of the labels is also controlled by an ultrasonic web tracking system that automatically compensates for positioning onto the can.

The can continues to a secondary roll-down assembly consisting of a moving belt on one side and a stationary pressure pad on the other that together wrap the label tightly around the spinning can. During this time, the trailing edge of the label is pressed down over the top of the leading edge with only a small amount of overlap to secure it fully.

The labeler uses B&H’s Wireless Glue System, which B&H says was made commercially available last spring. By adding additional suction to the label vacuum drum, B&H eliminated heated wires near the drum, which had been used to trap and burn off strings of adhesive.

Shriver says one of the biggest challenges to the entire project was finding an adhesive that would withstand the temperature associated with the shrink process. The hot melt adhesive supplier, Ashland Chemical (Columbus, OH), played a key role, he says. This involved development at an R&D laboratory in the United Kingdom, appropriate for a brew with the Irish heritage of Killian’s.

Gunning for heat

Labeled cans continue for 10’ to the 6’-long shrink tunnel. Due to the complex shape and shrink needed on the pub barrel cans, the tunnel was equipped with extra electrical heat guns so that a total of seven of the eight available guns are used, says Shriver. Temperature control is precise, as each gun has its own digital temperature controller and can be aimed separately.

Unlike straightwall cans, the pub barrel cans must be shrunk through the entire surface. “It took some effort and experimenting to get a setup to provide the proper shrink,” he says.

For the pub barrel can, the shrink is started at the center, then directed toward the label bottom by the next several guns and finished with heat directed toward the label top. Cans are in the tunnel about two to three seconds.

Shriver says not all guns are used for the Grid Iron Warriors promotion, which was “easier to do,” he says, because it involved straightwall cans.

When compared to a sleeve label operation, Shriver says the application rates are higher and the costs are lower for roll-fed labeling.

From the shrink tunnel, the pub barrel cans continue another 30’ to the palletizer, where they are assembled into banded, tier-sheeted loads of about 7귔 cans/pallet. The cans are shipped to Coors’ Elkton, VA, plant in the Shenandoah Valley.

At Elkton, the cans are depalletized and run through the current production equipment set up for straightwall 12-oz 209 cans. Shriver says the 211-diameter barrel can is slightly shorter in height than unshaped 209 cans. “Our filler, seamer and conveyors have to be adjusted” to accommodate the pub barrel cans, he says.

A side benefit of the wrapped cans is a “superiority” to litho-printed cans in terms of abrasion-resistance, Shriver says: “We see virtually no abrasion damage on these cans.”

A good-looking package to start with ends up looking good as can be in consumers’ hands.