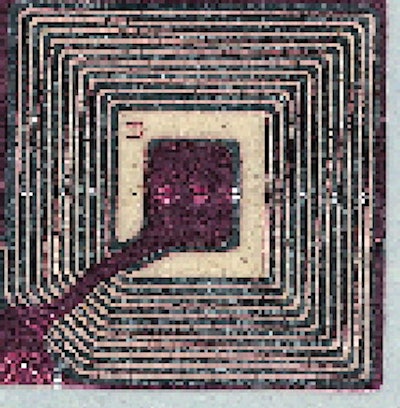

Imagine a local drug store displaying its high-end cameras or lithium batteries on shelves or pegs right alongside disposable products. Must be a store with a high rate of pilferage, right? But maybe not, since now, thanks to security labels in the packages used for high-end goods, pilferage is close to being tamed by many retailers. Whether referred to as source tagging or electronic article surveillance (EAS), the process is understood by consumers as the embarrassing alarm that sometimes sounds when someone attempts to leave a store without paying for the goods. What consumers probably don't realize is that retailers are embracing EAS to help change the way they do business-and cut losses. One company leading the way is Deerfield, IL-based Walgreen Co. Walgreens completed installation of Checkpoint Systems' (Thorofare, NJ) Impulse® alarm system in all of its 2곛 stores last year. Currently, there are two major technologies in the U.S. in the electronic article surveillance game: Checkpoint uses radio frequency technology; Sensormatic (Boca Raton, FL), employs acoustomagnetic technology (see sidebar, right.) See sidebar, p. 70, for information about a British technology. Both technologies revolve around the label or tag affixed to merchandise. They take many shapes. One of the first seen by consumers was the "hard tag," usually attached directly to apparel or shoes at the store level. Labels, affixed to packs at the store level or applied to packages by manufacturers, are a more recent medium. All systems use two other components: a deactivator, located near the bar-code scanner at the checkout aisle, and sensor gates, located near the exit doors in a store. An alarm system is triggered when someone passes through the gate with non-deactivated merchandise. One difference betwen the systems is that the respective sensors have diffferent sensitivities, permitting varied configurations at the exit doors. This is a factor that may persuade retailers to choose one system over another. You look at the whole package," says Ernie Locker, loss prevention manager of Walgreen Co. "You look at the ability to detect, the ability to place the tag, how you get deactivation, the overall rate of return, the ability to work with scanning systems. There's a whole range of things. You look to see how each works within your environment. "We talked to different manufacturers and retailers, and we did some test evaluations," he continues. However, he shies away from promoting one system over the other, stressing that, "for our environment, Checkpoint made the most sense." The RF system Checkpoint's Impulse label revolves around a radio frequency (RF) circuit that is aluminum-foil-based. Through a series of steps including laminating and etching, circuits are formed and adhesively applied to a paper carrier, which can then be applied to pressure-sensitive backing material. The labels measure about 11/2" x 11/4", with slight variations depending on application needs. These labels are available with moisture barriers for specific applications. They can be applied to packaging at the store level or by packaging converters or packagers. Some deactivators incorporate bar-code scanners; others can be retrofitted to existing scanners. Thus, when bar codes are being scanned for prices, RF tags are simultaneously deactivated. The RF tags and bar codes can be as distant as 15". Products with RF labels pass invisibly though sensors without disturbance; active labels, however, can be sensed from a distance of 5' from the sensor. Why EAS? Is shoplifting or product loss through "shrink" a problem costly enough to justify implementation of EAS? Consider this story about a Walgreens store in what's considered a low-crime area in Florida: "We had a busload of sixty seniors from a senior citizens' home that came every Tuesday and Friday to our store," says Locker. "We implemented the system on a Wednesday. On Friday, they came, and as they exited the store, we thought the system was malfunctioning: it sounded like a machine gun going off." An astute bus driver quickly realized what was happening and spoke with the store manager. After checking purchases against receipts, he recovered $3ꯠ of stolen product from the senior citizens. "They'd been doing that to us twice a week, fifty-two weeks a year, for the last ten years," Locker says. "In another [suburban Chicago] store, we caught fifty-eight shoplifters and recovered $4ꯠ in merchandise in our first week after implementation," he continues. "That story has been magnified across the country. I have no idea of the total we deterred, but in a few weeks, our grosses went up, our nets went up and we were able to support a higher number of sales with higher inventory." Walgreens began implementation of the system in August of 1995. As a test, it first defined its 200 highest risk stores and identified 550 of its highest theft items, including liquor, cigarettes, pain killers, and condoms. The company contacted manufacturers of these products and requested they attach the security label, inside the package. The results were so good that the company began a chain-wide implementation of the system. How did Walgreens convince manufacturers to apply an additional tag on its merchandise? Walgreens may not be as powerful a retailer as Wal-Mart, but when it speaks, manufacturers do listen. One way was by offering the prospect of increased sales by moving products formerly locked in a display case out onto the selling floor. Lynn Ingram, senior packaging engineer at Eastman Kodak, Rochester, NY, was one of the people Walgreens contacted initially for its test. "Walgreens' rationale was that they have a high rate of theft on film products," she explains. "To thwart that, they put film behind the counter so that the customer has to go to someone in the store and ask them for it. This really cuts down on our impulse sales. So we participated." Now, says Ingram, "Our strategy basically says that we'll work with any retailer on a source tagging program." Though she prefers not to get into details about costs, she says that Kodak is "offering this as a service to our retailers. We think it will help them better their bottom line." For at least some of Kodak's products, the security label is applied at Kodak's folding carton converting plant, PW has learned. Locker says there's been an EAS evolution. "A year ago, our stores received 826 SKUs with tags," says Locker. "Now, there are 1궏. A number of companies see this as a marketing tool, as a cost of doing business, a lot like the cost of advertising. Now manufacturers are coming to us, saying they want to offer this service. They know it's a growing request on the part of the retailers. "Ultimately," he adds, "what the manufacturer wants is the ability to increase sales and market share. Just like we're trying to meet the needs of our consumers, they're trying to meet their customers' needs." Tagging at the source An increasing amount of EAS labeling is done at the point-of-manufacture, also known as source tagging. Affixing labels from rollstock is claimed not to hinder production speeds. But having two major EAS technologies in the U.S. can prove a hindrance for many manufacturers. Much production is for inventory, not made-to-order. Thus a manufacturer may have to split its inventory between packages using each style of EAS label. But the alternative to manufacturers' labeling is tagging in-store, on the outside of the package. "This can destroy some of the ability of the product to sell itself," says Locker. "We try not to cover up any instructions of expiration dates, but when you have high-speed insertion of the tag inside the package, you have a concealed and higher quality placement. "When we started, nobody was tagging," Locker continues. "Now we've got a bunch of manufacturers. Every time one of us uses any of the EAS products, we all win because it increases the awareness and the number of SKUs that are tagged." The halo effect Though over 1ꯠ SKUs at Walgreens stores are source tagged, many still are not. For those products, Locker looks for what he calls "the halo effect." He elaborates: "There was a grocery chain in California that had a 4.21% shrink in liquor. It tagged 15 of 900 SKUs and shrink was reduced down to 2.11%." He hopes that the awareness of EAS will be enough to deter shoplifting. Other ways to cut costs include "fractional tagging," where one out of every two, or one in three packs contain a source tag. "The problem is that some managers would realize that only one of two or three was tagged, and then decide to tag every item," says Locker. "So some were double-tagged. That took twice the amount of tags, plus time. We're trying to keep this as simple as possible. "We haven't had any problems with our system," he says. Fewer problems is the whole point: "This is a deterrent system," he says. "We advertise our source tagging in the store for customer protection, and everybody wins. Walgreens wins in terms of less shrink. Customers win in terms of lower prices and open access to products. Manufacturers win in terms of sales." Besides cutting losses, the system has given Walgreens an improved merchandising plan. "Our merchandising evolution is to have all products out from behind the counter so that the customer can make hands-on decisions," Locker states.