This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

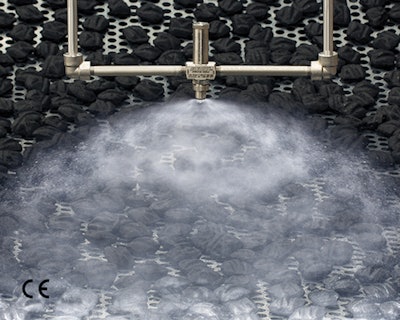

These can provide a smooth, even coating on the inside diameter of a pipe or similar ductwork. They are also effective for operations where mist over a broad area is needed, such as dust suppression, humidification and cooling. They combine liquid and compressed air inside of the air cap to produce the finest mist of atomized liquid that can be easily adjusted to meet the needs of your application. These spray nozzles provide liquid flows from 1.6 to 14.7 gallons per hour with liquids up to 300 centipoise.

Exair’s patented no drip valve assembly stops liquid flow when air pressure is shut off. This stops post spray drip which can ruin product finishes on painted or coated surfaces. No drip atomizing spray nozzles are also an important tool for saving expensive coatings and chemicals or conserving water. They can be used with water, light oils, chemicals, rust inhibitors, paints, and dyes.

The stainless steel construction of these no drip atomizing nozzles adds to their durability and corrosion resistance. Exair No Drip atomizing nozzles are available with 1/8 NPT, 1/4 NPT and 1/2 NPT connections and in a variety of sizes and shapes to meet your needs. All models come with a 5 year Built to Last Warranty and are CE compliant. No drip internal mix 360 degree hollow circular pattern spray nozzles ship from stock and start at $383.