This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The time required to securely pin a rack with two pin holes, for example, is reduced from 1/2 or 3/4 of an hour to not much more than a minute as a result. The rack can also be replaced quickly and easily for servicing.

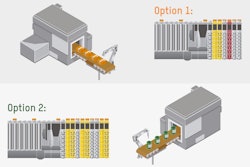

This innovative pinning method highlights very clearly how Wittenstein alpha thinks outside the box – in terms of systems rather than isolated drive solutions. The ergonomic and efficient alternative to screw clamps for rack installation benefits users with a time saving of up to fifty percent. Thanks to Wittenstein alpha’s new INIRA pinning concept, the time required to install a rack is now significantly shorter.

Chips and swarf are always undesirable during assembly work: they are difficult to control and have a destructive effect. Wittenstein alpha’s new chipless pinning principle successfully amends a proven method that was first established in the market several decades ago; it was developed in response to customer demands for quick and easy assembly.

Chipless pinning offers numerous advantages for machine builders: instead of drilling and reaming the rack and the machine bed together in a time consuming process and then driving in the pin, this innovative, two-piece assembly solution from Wittenstein alpha facilitates a secure and completely chipless connection! The holes which are required in the bed can be machined to fit exactly when the components are manufactured – in a single setting with the fixing holes. The two-piece mounting kit is comprised of a special pin and sleeve, which are fitted together using just a hammer and an Allen key. The time saving as a result of this chipless assembly process is quite substantial: each rack can be securely fixed with a positive connection in less than 60 seconds – compared to 35 or 40 minutes with conventional pinning. Easy dismantling and reusability mean the rack can be exchanged rapidly in case of repairs or retrofits.