Comprised of six integrated products for industrial big data management and analytics, GE Intelligent Platforms’ new Proficy Monitoring & Analysis software suite Access to Data in the Cloud allows companies to manage equipment and process data by captutring, storing, contextualizing, and analyzing data, provides access to data in the Cloud, and presents actionable insights for fast and effective decision making.

GE Intelligent Platforms’ new Proficy Monitoring & Analysis six integrated products include: Proficy Historian, GE¹s flagship data collection software; Proficy Historian Analysis for data mining and visualization; Proficy SmartSignal for predictive analytics for condition-based monitoring; and Proficy CSense to troubleshoot process problems, monitor process health and create close loop process optimization.

Two additional products are new to the offering and include Proficy Historian HD that allows storage of massively large data sets in a Hadoop cluster, and Proficy Knowledge Center, a console that ties the solution together with process visibility, asset health assessment and process optimization.

Proficy Historian HD combines industrial data and analytics with elastic capacity creating a Big Data solution built on Hadoop; The software facilitates advanced analytics on industrial big data to improve process performance, troubleshoot process problems, and predict and prevent asset failures.

Historian HD enables users to bring together an entire set of historical time-series data while reducing data storage costs by as much as 85%.

Another new part of the suite is Proficy Knowledge Center, a model-driven, browser-based visualization application. Tightly coupling an asset data model with historical time-series data, Proficy Knowledge Center supports unified views of process health and equipment health for increasing productivity and decision making. The solution builds on Proficy Historian to efficiently store and display immense amounts of time-series data. Results of data analyzed by Proficy CSense or Proficy SmartSignal are then visualized through the Knowledge Center in model context making it easy to navigate and understand.

The Proficy Monitoring & Analysis software suite can be used remotely to monitor one plant or all of a company¹s global operations. As a result, it provides information to increase equipment availability and reduce unplanned downtime, improve yield and reduce variability, and reduce maintenance costs and inventory.

The Proficy Monitoring & Analysis suite provides four essential capabilities:

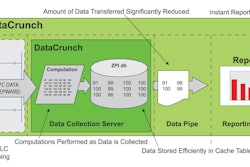

Improved data management: The platform can manage and aggregate all time-series data and process data for authorized personnel anywhere with access to a web browser. Large volumes of real-time data can be collected, archived, and distributed at extremely high speeds and low storage costs in the Cloud. More data over longer periods of time can allow advanced analysis and greater insight into actual versus optimal equipment and process performance‹leading to a competitive advantage.

Improved asset health: Using advanced predictive analytics and diagnostics, companies can monitor all critical assets automatically and continuously, 24 hours/day. The software learns normal asset behavior and detects variances to provide early warnings of impending problems, with diagnoses of equipment and process failures and prioritizations based on severity. Early warning reduces catastrophic equipment failure and enables proactive versus costly reactive maintenance.

Process optimization: The software also optimizes processes with advanced analytics that identify unknown correlations in process variables that can lead to sub-optimal performance. It allows for what-if analysis to find solutions that optimize processes at the same time optimizing for asset health. Process optimization increases yield, while reducing variability.

Data visualization: The suite features web-based reporting to deliver role- and asset-based information that unlocks the value of the data in context to the right person at the right time.