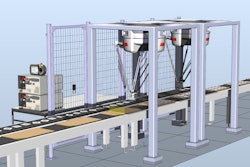

AMF Bakery Systems, the world’s leading manufacturer of high speed bakery equipment, makes robotic systems that commercial bakeries use to transfer freshly baked buns and other products from primary packaging lines to bread trays bound for distribution centers. The company saw a need in the market for a flexible, light-weight, end-of-arm robotic tooling with a dense population of vacuum cups. AMF envisioned that each cup could be independently turned on and off, allowing the same tooling to pick and pack different patterns of products.

Existing solutions required the tooling to be changed out for each different loading pattern or product size. This extended changeover times, and in some cases it required maintenance engineers to perform the changeovers instead of the line operators. The existing methods also required the sub-elements of the pick patterns to be isolated as the tooling would pick up whichever product was underneath it in the pick area. In other words, if the pick pattern were two packages of buns, for example, only two packages could be sent down the conveyor to the robot at a time.

On some production lines, buns had to be packed into trays by hand because the tooling in use could not do the required pick and place. This situation, of course, required substantial labor.

Festo helped AMF Bakery Systems design a programmable dense-cup-population tooling that solved these problems on the packaging line. The new system quickly became part of AMF Bakery Systems standard offering and remains so today. The tool design and the design for supplying vacuum, a path for both electrical and control cables to the tool, proved unique enough to have patented.

“Weight limitations of the robot were a primary concern, as was size,” said Roy A. Miller, Senior Sales Engineer, Festo. “So Festo began the design process by identifying a small, lightweight, single-acting pneumatic cylinder with return spring—the Festo EFK—that would be used to turn on and off each vacuum cup.”

Dave Thomas, Senior Applications Engineer at Festo, adds this. “To control the cylinders, Festo included a CPV10 valve manifold. This was also a lightweight and small solution—engineered for tight spaces. AMF’s engineers put eight different manifolds on the end-of-arm tool, bringing the manifolds as close as possible to the EFK cylinders. Each CPV10 manifold had 16 valves. This was sufficient to control all 128 vacuum cups.”

Only one airline was needed to bring air to the end-of-arm tooling. At the end-of-arm tool the air was split into eight lines, one for each manifold. Also on the end-of-arm tool was an Ethernet/IP gateway. This limited the number of communication cables that were required to be run down the robot arm.

The CPV10 manifold integrated to the Festo CPX control platform. With this arrangement, all 128 vacuum cups can be controlled individually. AMF chose a pneumatic solution over others as it met functionality, weight, and control needs. The physical size worked well with the size of the tooling and the available area on it for mounting the valve controls. The simplicity of the valve control also met AMF Bakery Systems expectations for keeping the complexity level low to ease maintenance interactions with the valve controls.

“AMF Baking Systems realized its vision for a better packaging line,” said John J. Keane III, Executive Product Manager Packaging and Automation, AMF Bakery Systems. “The new system has eliminated changeover time and increased production rates.

“Customers around the world rely on AMF’s expertise in the high speed bread, bun, and soft roll baking market. The programmable dense-cup-population tooling is an example of how the company works diligently to produce solutions that represent industry leading quality, innovation, and value.”