This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

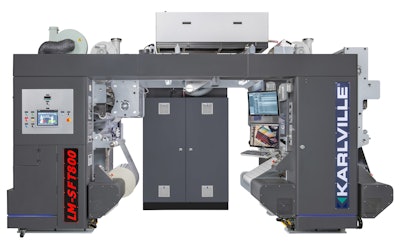

Karlville’s COMBI Thermal + Solventless Laminator features include:

• Proven thermal lamination technology with adjustable wrap angle and precise tension control.

• Proven solventless adhesive technology with 5 roller coating system.

• Excellent Dosing via geared pump Bi-2 Mixer.

• Accurate Adhesive Coat Width via Sleeved Transfer Roller.

• Precise Coat Weight Measurement via Inline Infrared Sensor.

• Closed Loop Tension Control via Dancer.

• VPN Access for Service.

• Ideal for HP Indigo 6900 and HP Indigo 20000 Presses.

• Optional LASX Laser Window Cutting Turnkey Accessory.