The following highlights were extracted from the report “Implementation Guidelines” Version 0.2, copyright MIT Auto-ID Labs. The recommendations are based on research conducted by the MIT Packaging and RFID Special Interest Group at the Massachusetts Institute of Technology, Cambridge, MA.

Introduction

The ultimate goal in an RFID system is to maximize the communication link between the reader and the tags while at the same time, minimizing the detrimental effects of the local environment. The ultra-high frequency bands (868-950 MHz) used in RFID systems present unique problems in transmission, reflection, and absorption that are not encountered at lower frequencies.

Through a series of theoretical and experimental studies carried out at the MIT Auto-ID Labs, researchers have compiled a set of basic guidelines that are intended to help end users to improve the performance of RFID systems.

One of the basic properties studied is the dielectric constant. Research director Daniel Engels explains that materials with a higher dielectric constant means it’s harder for the RF waves to pass through that material. Materials with lower dielectric constants allow more power to pass through or be absorbed and less is reflected back.

Speed of pallet through portal: Movement of tags causes signal modulation; UHF readers are affected by phase shifting caused by moving tags.

Time required to identify all case tags that are on a pallet load:

No. of Tags Time required to be in the RF field

1 tag 0.4 seconds

32 tags 12.8 seconds

256 tags 102.4 seconds

Pallet dimensions (ft) Reader antennas needed

3x3x3' 1 reader-antenna

5x5x5' 2 reader-antennas

10x10x10 ' 7 reader-antenna

Small number of reflections

* Materials with a high dielectric constant can reflect power to the center and middle of pallet loads.

* Materials with low dielectric constant should be grouped together to create more nonreflective areas.

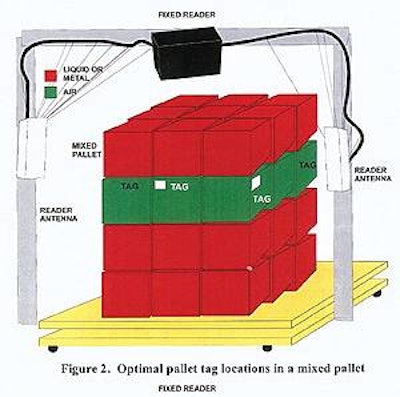

* With a mixed pallet, place a tag outside a case containing a material with low dielectric constant.

* With a single SKU pallet containing products made of high dielectric constant material, place a pallet tag on any of the facings nearest to the reader antenna.

Other findings:

* Group easily penetrated materials such as paper together in order to channel electromagnetic power to the center of the pallet.

* Use air gaps in cases with low dielectric constant layers to minimize reflection as well as to penetrate to the center of the pallet.

* With a mixed pallet, keep conductive layers (those with high dielectric constants) at least half a wavelength apart by placing low dielectric constant materials between them.

* Power that is channeled through air gaps in cases can be maximized by staggering tags along a pallet.

* If a case contains a high dielectric constant product along with an air gap, a tag should be placed on the case where the air gap is located.

* As a tag passes through the RF field, the face of the tag should be parallel to the face of the reader-antenna.

For further information on this and other MIT RFID projects, you can reach MIT Auto-ID Labs research director Dr. Daniel Engels at the contact below.