As the craft brewing industry continues to capture increased market share, the pressure for increased production volume creates the envious complication of navigating new coding and marking challenges. Though there is a logistical need to meet lot and batch tracing requirements (and often to comply with Brewer Association recommendations for packaging or “best by” date labeling), craft brewers are eager to keep their time and financial resources focused on the delicious brews they are passionate about. This means ideal marking and coding solutions need to be cost-effective, reliable, and low-maintenance.

Given the wide range of available technologies, how can craft brewers identify coding and marking technology best suited to meet their unique needs? Here is a list of key considerations for craft brewers to keep in mind when considering available options.

Supplier considerations

Craft brewers are often eager to grow at a pace that is aggressive but allows them to maintain top quality. A key component in this is to identify a coding and marking supplier well-equipped to meet their unique coding and marking needs. When starting out, craft brewers do not need massive systems designed for more industrial, ultra-high volume beverage corporations. But neither do they want to be boxed in or limited by basic technologies that will not grow alongside their business. Instead, they need highly scalable technologies that can adapt and grow as production expands. To find just the right fit, craft brewers need to identify a supplier that offers the following characteristics.

Wide technology offering—Identifying a supplier with a wide technology offering including CIJ (continuous ink-jet), laser, carton coding, and labeling solutions can help ensure that craft brewers find the best possible system for their unique needs. A supplier familiar with all of these technologies can speak honestly about the pros and cons of each with a focus on finding the best technology for each unique brewer. Also, a supplier that can provide quality coding and marking solutions for both primary and secondary packaging can simplify operations by providing a single point of contact.

Price tag transparency—To avoid costly surprises, don’t be seduced by low sticker prices. A little extra time invested up front in studying features included and excluded can save a great deal of time and expense down the road. Key performance features to look for are presented in more detail below. However, “hidden” costs often include sensors for labeling technologies and print heads for ink-jet systems. Labeling technologies often require sensors that indicate when labels are running low, when a label is present, and what height a package is for proper operation. Each of these three sensors can easily add $300 to $500 to a price tag, raising the actual cost by as much as $1,500. When comparing ink-jet systems for carton coding, the lifespan of an ink-jet print head can vary from three months to 10 years. Making sure you select an ink-jet system with a durable, repairable print head can lead to significant cost savings.

Automation & integration support—As a craft brewer grows, increased production requires a shift to automated filling and packaging lines. In addition to selecting coding and marking equipment, the craft brewer will need to install and integrate various material handling technologies such as conveyor belts and unscrambling tables. In order to keep precious time and resources focused on quality beer, it is extremely helpful to find a coding system supplier that can cost-effectively serve as project manager in getting your automated lines up and running. Such a supplier can provide you with a number of technology options within your budget range and take care of installation, integration, and training to leave you with a fully automated line.

Strong service support—For many growing craft brewers, a coding and marking system is the first industrial printer they have purchased. Unlike common desktop printers that users are familiar with, these printers will require regular maintenance to avoid costly downtime. When comparing technology options look for technologies that offer market-leading durability and reliability as well as suppliers that offer cost-effective national service support. Check to see if the technology is designed to allow you to quickly and easily do regular maintenance yourself to save time and money. Also make sure your supplier is available to provide regular (typically every 18 months) product service and emergency support to avoid downtime in case you have any production issues.

Primary packaging considerations

Different printers are needed for printing on your primary package (bottle or can) compared to your secondary package (outer carton or case). Continuous ink-jet (CIJ) and laser are the most common options for printing text, graphics, barcodes, QR codes and other codes onto primary beverage packages. The points below can help a craft brewer identify the technology that best suits its unique needs.

Package type—When selecting a coding system for your primary packaging, the first step is to consider what type of material you will be printing on. Keeping in mind that you can reasonably expect the printer to last five to seven years, what types of packages are you using now and do you plan to use in the years ahead? Bottles can be coded with either laser or CIJ systems. Cans are coded with CIJ technology. This means that a craft brewer who wants to be able to code on both cans and bottles will need a CIJ system.

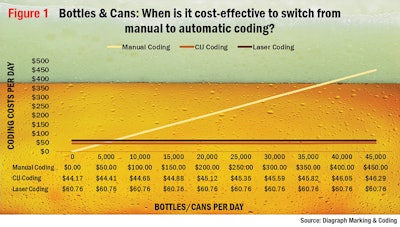

Production volume—At what volume of production does automated coding become more cost effective than manual coding of beverage packages? Assuming that manual application involves table-top printing directly onto a label before applying and that automated costs include up-front capital as well as daily consumables and parts/service, the answer is when daily production reaches roughly 4,500 units for CIJ and approximately 6,000 units for laser. (Figure 1.)

Features to look for in a CIJ printer—There are a number of quality CIJ technologies available that offer reliable, high-quality printing onto both bottles and cans. When comparing systems, it’s helpful for a craft brewer to look for these features: