Champion Laboratories, headquartered in Albion, IL, is a leading private-label manufacturer of filtration products for the automotive, heavy-duty, off-highway, industrial, agricultural, construction, mining, marine, and fuel-dispensing industries. Champion Labs operates nine separate manufacturing and distribution facilities and produces more than two million filters weekly—including oil, air, fuel, water, and transmission filters. The company also fabricates virtually all component parts that go into the filters. These filter products are distributed under Champ, Kleener, Luberfiner, PetroClear, Eurofilter, and a variety of other brand names.

Champion uses the A Series ink-jet printing system from Domino Amjet (www.dominoamjet.com) to identify “in process” parts and finished goods. And the company uses the Domino Amjet C Series printing system to apply custom graphics to corrugated shipping cases. Printing speeds are approximately 200 parts per minute and 33 cases per minute.

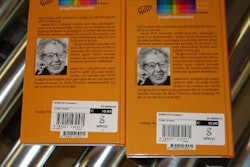

Various Champion Labs’ products are painted white, blue, or black, and the label graphics are unlimited. Champion likes to use yellow inks to present a good contrast on the company’s black and dark-colored products. But as Champion Labs manufacturing technician Mike Keepes explains, “The inherent problem with yellow and white inks that we have used in the past is that these inks are pigmented and require special equipment and/or methods to keep the pigments in suspension. The Domino yellow ink is a ‘soft pigment ink’ that stays in suspension without any special equipment and runs very well on their standard A Series printers. This has allowed us to eliminate specialty printers that require more service and attention and to standardize on one printer model.”