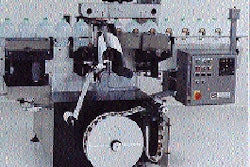

Fresh red meats vacuum-packaged in barrier films have never quite caught on in the U.S. Despite the 14-day shelf life such packaging provides and all the distribution advantages that come with it, retailers have been slow to embrace it, primarily because consumers don't like the dark red, almost purplish color the meat takes on in its oxygen-deprived state. Now vacuum-packaged fresh red meats are making another bid for a place in the supermarket meat case. This time they have new packaging technology on their side: a multilayer lidding stock with a peelable barrier layer. Like the flexible films used in other vacuum-packaged meats, the film extends shelf life to 14 days by keeping out oxygen. But its barrier component can be peeled off easily by workers at the supermarket just before the trayed pack is to be placed in the display case. When this peelable layer is removed, all that remains over the meat is a clear film that is permeable to oxygen. About 20 minutes later the meat blooms from its oxygen-starved purple to the bright red color that shoppers like. After the barrier component is removed, the meat package will have three days of shelf life. Developed by Cryovac (Duncan, SC) for Lucerne Foods Ltd. and parent Safeway Canada, the vacuum package is now available in 78 of 221 Safeway Canada stores. Lucerne is Safeway Canada's primary meat supplier and is located in Calgary, Alberta, Canada. According to Safeway's Jim Waters, vice president of public relations and government affairs, the vacuum-packaged meat program began late last year and is still in its test stages. The prognosis of the test thus far, adds Waters, is promising. Confirmation of the package's potential came June 22 when the Packaging Assn. of Canada gave the packaging concept top honors in its 1995 National Packaging Competition. The package was one of two recipients of the Chairman's Choice Award for packaging excellence. "Lucerne Foods is the first company in the world to commercially use this material," says Bill Leigh, PAC competition chairman and graphics manager for Kraft Canada Inc. "Its shelf life-extending properties enable Lucerne to more effectively distribute packaged meats from a central location." Goal is efficiency Like any program involving centrally processed case-ready meat, a key objective behind the new package is greater efficiency and the cost savings that come with it. Rather than having skilled meat cutters in the back room of each store-meat cutters who, it should be noted, are becoming increasingly difficult to find-the number of personnel at the store level can be reduced and the cutting can be done in a more automated fashion in a central processing plant. "We anticipate that if it were introduced in all our stores, there'd be a significant savings in labor costs," says Waters. "But at this stage we haven't drawn any firm conclusions about costs." He adds that the cost to consumers is unchanged. A steak prepared conventionally on a foam tray is priced the same per pound as the same steak in the peelable barrier film. Labor savings is only one objective. Quality and consistency of product is another. So is flexibility. "It gives stores more flexibility in ordering product," says Waters. "If a store doesn't need a primal or subprimal to satisfy a particular product requirement, they can order less." This flexibility extends right on through to the way the meat department stocks its meat case. For example, if it's Sunday afternoon and the meat case is devoid of T-bone steaks, meat department workers can peel the barrier film from one or two steaks and quickly remedy that out-of-stock situation. If the store didn't have a case-ready meat program, a primal or subprimal would have to be removed from its vacuum-packed barrier bag to be sliced and trayed. Meat department managers are unlikely to cut primals on a Sunday afternoon because the shelf life clock would start ticking on all those sliced and packaged steaks even though the likelihood of selling that many wouldn't be very good. So in all probability, the T-bones would simply remain out of stock. Any customer who wanted one would be disappointed-not a good thing in the fiercely competitive grocery business. Even if the store had a case-ready meat program using modified-atmosphere master packs, the customer might still be unsatisfied. That's because once the master pack of 10 or 20 meat packages is opened, all of those nonbarrier packages are now just three days away from markdown. Structure's a secret Unfortunately, Cryovac is less than forthcoming about the makeup of the packaging materials used in the Lucerne package. Walker Stockley, market development manager at Cryovac, says the clear nonforming top web has a total thickness in the 6-mil range. He doesn't say what the barrier material is, though PW sources suggest that it's ethylene vinyl alcohol copolymer. Presumably the same material provides needed barrier in the 9.5-mil white opaque forming web. The machine on which the packages are formed and sealed is a CD-6000 from Multivac (Kansas City, MO). Like other CD-6000s, it uses a unique process to heat the lidding material and apply it to the formed tray with no need for sealing tools. But unlike other machines in its series, it prevents the lidding material from adhering to one critical half-inch strip on one end of each tray. This gives the supermarket meat department people a flap that's easy to grab onto when it comes time to peel back the barrier. The first step in the production sequence is thermoforming of the bottom web into shallow trays. Forming is done one-, two- or three-across but always two-deep in the machine direction. The largest tray, formed one-across, is used in two different ways. One is the "Family Pack," where two or three cuts are placed adjacent to and touching each other. The other approach is to keep two cuts of meat separated by several inches. Typically this is used for premium cuts of beef, which display nicely when arranged this way. The best way to understand how the easy-to-grab flap is produced is to walk through the six-up production sequence. First, meat cuts are loaded manually onto the six formed trays, which are aligned three across the machine direction and two deep. The space between the leading three and the trailing three trays becomes the area to which the lidding material does not adhere. An MR pressure-sensitive labeler, also from Multivac, applies a clear one-inch wide strip of polyester in precisely this location. In the next station, where the lidding material is applied, this strip alone resists adherence to the lidstock because the polyester strip blocks a heat-seal coating on the tray material. Preheat before sealing dome While all this is going on, the lidstock unwinds from its roll and passes through a preheat station that exposes the material to 130°C heat. Partially softened, the material drapes over the thermoforms and their load of beef just before a vacuum seal dome closes on the six cavities. Inside the dome, the lidding material is vacuumed up from the product and into a heated dome, where the temperature is 200°C. Then outside air is introduced into the dome in a controlled manner that breaks the vacuum and allows the now nearly liquified lidstock to fall down from the dome. As it does so, it forms tightly around the contour of the meat and bonds firmly to the white forming web everywhere except where the pressure-sensitive material has been applied. "It's a surprising revelation to most everybody who inquires, but no, the layers of the lidding material do not separate in the heated dome," says Cryovac's Stockley. Now the sealing dome opens and the lidded trays enter a station whose tooling produces two perforations across the web, one on each side of the p-s polyester strip. The web indexes again and two steel rules cut across the machine direction. One cuts right down the center of the polyester strip; thus the leading three packs have a 1/2-inch no-stick strip on their trailing edge and the trailing three packs have the same strip on their leading edge. The other rule cuts the trailing three packages from the continuous web of forming material. Corner rounding is done by these steel rules as well. Then the two three-packs move through longitudinal cutting by rotary knives that separate the trays into individual units. Why the perforations? To help meat department workers peel the barrier web in a single piece. When the worker grabs the 1/2-inch flap, he has a grip on the entire lidding material. But as he peels past the perforation a half inch from the edge, the perf separates the barrier from the nonbarrier layer; the worker peels off the barrier layer only. The non-barrier film remains in place, tightly hugging the contours of the meat and keeping purge to an absolute minimum. Cycle time is about 18 seconds, so on one Multivac system Lucerne can produce about 6 large trays per minute, 13 medium or 20 small ones. Gaining an edge As Safeway's Waters sees it, vacuum-packaging of fresh red meat has the potential to give Safeway a competitive edge. "Passing some of the savings along to consumers is likely to be our approach," he says. "It all depends. Currently meat prices are very competitive. Every retailer is looking for an edge. But even if pricing isn't our edge, the other advantage this gives us is that any time, day or night, it's much easier to prevent out of stocks." Waters acknowledges that back room operations change considerably when the case-ready program enters the picture. "Instead of cutting, they're peeling," he observes. At least they are for the 26 specific cuts that are vacuum-packaged. Conventional foam trays haven't disappeared from the 78 stores now carrying the centrally prepared meats. Currently the vacuum-packaged cuts represent about 35% of a store's typical meat case offering. And no cut is displayed in both package styles. The other change in personnel deployment that comes with the case-ready program is that people who formerly spent little time with customers and stayed in the back room for the most part can now be brought out into the store to help merchandise meat. Waters says the response of Safeway's in-store personnel, members of the United Food and Commercial Workers union, has generally been good. "They accept the fact that innovation is the name of the game, and that perhaps compared to other departments of a supermarket the meat counter hasn't changed much," says Waters. "That lack of change might be about to undergo quite a transformation."