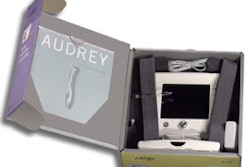

For decades, electrostatic discharge (ESD) bags have functioned as the primary package to protect computer hard disk drives. Seagate Technology, Inc. used the bags for years for its own drives. But late last year the Scotts Valley, CA, firm switched to a rigid one-piece hinged clamshell that it created exclusively to protect its drives, which it spells “disc.” Unlike the bags, the rigid clamshell provides shock protection during product handling and shipment.

Called SeaShell™, Seagate’s patent-pending package is thermoformed by Ivex Packaging (Cumberland, RI). Ivex is the sole producer of SeaShell domestically and the primary thermoformer of the clamshell in the foreign markets Seagate serves. Seagate relies on a single material supplier, Klöckner Pentaplast of America (Gordonsville, VA), for the 20-mil sheet used to thermoform the protective pack.

“ESD bags have been the disc drive industry standard since the early ’70s,” says Ron Matheison, Seagate’s manager of corporate packaging. “But we needed shock protection that the bags could not provide.” While training workers on proper handling techniques helped, there was still room for improvement, he adds.

Seagate has done just that. The company says the pack has reduced damaged product returns by 60% and saved $4.8 million per year in materials and shipping costs.

Seagate designed and developed SeaShell, which it began using in September ’99. Ivex made prototype “one-up” molds of Seagate designs during the development process. The project was spearheaded by executive director of quality Troy Merrell, with key contributors Matheison, senior packaging engineers Todd Redder and Jay Hazekamp, and Ivex sales director Craig Metheany.

Less handling

The key benefit SeaShell provides, says Matheison, “is reducing handling damage. We have 60 percent fewer drives coming back from our customers due to damage.” Most damage comes from handling, he says, and can occur at any point in the integration or distribution process.

“The human body is the largest generator of ESD,” he points out, “and there was a lot of handling with the ESD bags.” The clear clamshell eliminates one major handling step compared to the bag: scanning. “We apply a bar-coded label to the drive itself, and our customers scan the label for information about the drive,” says Matheison. “The scanner could not read the code through the bag, so customers would have to pull them out to scan them. Now they scan right through the clamshell.” That reduces handling of the part and the potential for ESD damage.

“No matter where it happens, a damaged drive is going to cost Seagate money to repair, handle and ship out another drive,” notes Matheison. Fewer returns, of course, translate into more satisfied customers, which is another crucial benefit for Seagate. But the financial advantages are no small change, either.

Cost savings

“The clamshell provides extra protection for the drives, and because of that, we’ve been able to reduce the height of our outer shipping case that holds 20 drives,” says Matheison. “We reduced the height enough to put another row of product onto each pallet. We went from packing 640 drives per pallet to 800. That’s five tiers compared to four before. We’re saving $1.2 million per quarter on shipping, material and damage-reduction costs.”

Matheison adds that by putting an extra tier on a pallet, “the company ships 25 percent fewer pallet loads. This means 25 percent less handling, storage, pallet marshalling, cargo hold space, customer handling, et cetera. There is currently a premium cost for cargo space on planes leaving the Far East where our products are produced. By reducing the space we take up on each plane, we reduce this premium. That’s extremely critical during the holiday season, as demand for cargo space increases exponentially.”

Seagate uses corrugated shippers and molded, expanded polypropylene foam pieces to ship SeaShell-packed drives. The foam is molded with slots so that 20 clamshell-packed disc drives can be loaded on-end in the bottom foam cushion, in a 2x10 configuration. Another cushion fits on top of the drives in the shipping case. Cases and foam are sourced from a variety of vendors, primarily in the Far East.

Benefits offset costs

The financial advantages are important because there were trade-offs in making the material switch for the disc drive package. The primary difference: cost. “There’s about a 200-percent upcharge for the clamshell,” admits Matheison.

“In the beginning, the key hurdle in implementing the change was the cost of the SeaShell,” Matheison recalls. “That was rather difficult, so we looked at finding the cheapest materials we could find that would still meet our requirements for shock protection, and they were readily available in Asia. We came up with a couple of materials that would work and selected the one we felt was best. We did extensive testing and chose polyvinyl chloride.”

The other trade-off concerned ESD protection. While the clamshell provides adequate ESD protection, he admits it’s not as ESD-protective as the bags. “But the question was how much protection do we need?” After considerable testing, Seagate determined the trade-off would sufficiently protect the drives.

The SeaShell package was honored during Pack Expo International 2000 with a Best of (Electronics) Category AmeriStar award by the Institute of Packaging Professionals (Herndon, VA). It also won a Worldstar for Packaging Award in the Retail; Consumer Electronics Div. from the World Packaging Organisation (Herndon, VA).

Material switch

Initially, Seagate used Klöckner’s PVC for the SeaShell, but recently switched to the vendor’s Pentastat® AS KPET/56 amorphous polyethylene terephthalate (APET) sheet, again using a 20-mil thickness.

“We educated our customers about PVC,” Matheison says. “The only issue with recyclability was finding someone to do it. There’s a market for PVC regrind, but we received a lot of flak for using it, so we began to phase in APET in October.”

The economics of the switch are complex because of resin price fluctuations, but Matheison says there’s at least a 15% savings with the switch, in part because the current clamshell is slightly smaller than its original version, so less material is necessary.

APET also yields “better clarity and ESD properties,” he believes. “And the shock and vibration characteristics are very similar to that of PVC. We can use the same molds and machinery, with only a few small machinery tweaks and processing changes necessary. It’s been a very smooth transition.”

With more than a year’s experience, Matheison summarizes the switch to the SeaShell. “With the clamshell, we’ve eliminated the excess handling of the drive. We’ve seen damaged product returns diminish significantly, and we believe it’s due to the fact that people don’t have to handle the drive as often as they did with the bags. We’re paying more up front, but the savings and reduced damage returns more than justify the change.”

See sidebar to this article: Seagate serves two customer ‘streams’