This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

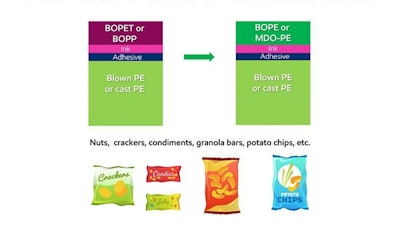

ExxonMobil’s HD7165L is an HDPE grade for machine direction oriented (MDO) PE film applications. Offering excellent optical properties and outstanding mechanical properties, it is well suited to help enable mono-material laminated packaging that can be used to package products like nuts, crackers, condiments, granola bars, and potato chips.

“The development of new HD7165L has been driven by market demand from brand owners and processors looking to develop all-PE packaging which, in turn, has created a need for print webs made of blown MDO-PE films,” said Nilesh Savargaonkar Principal Customer and Application Development Engineer, ExxonMobil.

ExxonMobil HD7165L can help enable converters to produce blown MDO-PE films with 60% to 70% HDPE for enhanced stiffness and high heat resistance. High output rates in excess of 400kg/hr are possible, while bubble stability is maintained.

High MDO stretch ratios as high as 7:1, with very high stiffness (1% secant modulus as high as >200 kpsi) can be achieved. With haze less than 10% and gloss higher than 60%, ExxonMobil HD7165L offers excellent optical properties. Used as a print web of a PE-PE laminate, ExxonMobil HD7165L offers high heat resistance, stiffness for a lack of extensibility, and excellent printability for optimum brand promotion.

In blown MDO-PE film applications, ExxonMobil HD7165L offers high, uniform orientation, gauge stability, and low gels for easy processability.

Compared to a market reference HDPE grade (density 0.962 g/cm³), ExxonMobil HD7165L (density 0.961 g/cm³) delivers better shear thinning behavior and extrudability, higher melt strength for bubble stability, excellent orientability, and gauge uniformity.