Among the industry’s leading experts in the field of radio-frequency identification, John Greaves was recently lured away from his own company, ePC Group, to join Deloitte Consulting LLP, a well-known consultancy with offices worldwide. As global firm director for RFID, he heads up Deloitte’s activities on the RFID front.

Greaves took time out of his busy schedule this past summer to visit with editor Patrick Reynolds and technical editor Rick Lingle at Packaging World’s Chicago office. Despite several wireless interruptions from leading consumer packaged goods companies that are among his clients, Greaves deftly and energetically revealed his view of RFID’s impact on packaging.

PW: How do we even begin talking about RFID and its impact on packaging?

Greaves: First of all, RFID is a well-established technology, it’s not something Wal-Mart invented. Wal-Mart plays a vitally important part in RFID and has the most impact for your readership, more so than the Department of Defense’s initiative. RFID is really about WEC—wireless-enabled commerce, whether it’s tracking P&G diapers or sneakers in a shoebox. And that’s why Wal-Mart got involved.

PW: Doesn’t ‘WEC’ take RFID outside the realm of packaging?

Greaves: No, actually it takes it more into packaging. That’s why packagers are so strongly impacted by RFID, including the cost of deployment. They will also have to determine where that tag will go. Reengineering of packaging will increase—we will see changes to corrugated cases as a result because that’s often where the tag will be placed.

PW: What are the reasons for packagers to adopt RFID?

Greaves: There are three immediate reasons to adopt. I call them FCA—federal, commercial, advantage. In the case of federal, you adopt RFID, possibly for something like pharmaceuticals, because a law requires it. For commercial, it’s because [a company] like Wal-Mart has told you to. Or, finally, you adopt RFID because you see that your use of the technology can create for you a competitive or business advantage.

PW: Can you compare the bar code with RFID?

Greaves: The problem is that the bar code is yesterday’s news, it’s undynamic. Once printed, a bar code remains in that state forever. Another difference is that radio-frequency anything is subject to regulation—nothing that has ever been used in the supply chain before has had regulation built around it of the scope of RFID. You have to recall that the bar code was a pretty complex undertaking, too. If you changed a historical article from bar code to RFID, you can see a similar genesis. The only difference is that the bar code was already eight years old before Wal-Mart adopted it, and there was single-digit adoption in terms of percentage across the market. This time it’s the other way around.

PW: What does that mean for packagers?

Greaves: It is essential for packagers to come to market very rapidly with RFID-enabled packaging solutions. The first into production with minimal pricing impact as a result of innovation and adoption, flexible approach, and clear understanding will have competitive advantage on an enormous scale.

PW: What are your thoughts about Wal-Mart’s role in RFID?

Greaves: Wal-Mart understands that all the [data] infrastructure in place is warped and wobbly, and to make RFID work, hundreds of millions of dollars are needed to resolve these challenges. Wal-Mart understands best of all that we cannot simply apply RFID over the current infrastructure; otherwise, it would topple, and for that alone I think they are superb. In terms of RFID and Wal-Mart’s determination to adopt it, and their understanding of what the challenges are, they are outstanding and have done a thorough and exhaustive job. Wal-Mart recognizes that the foundation of RFID is data synchronization.

PW: What is data synchronization, and why is it important?

Greaves: Let me illustrate it this way: Stick an RFID tag on a package, yawn. Make an RFID antenna work in the warehouse, hohum. But tell me you can transmit the data from those RFID readers from that warehouse to your global data center in Toledo, and I say, congratulations! Provide data integrity, data synchronization, data cataloging, and data transfer, and now we’re talking! It gives packagers the ability to call forward the correct amount of packaging for their next order because now they know the real amount of goods that need to be produced. That’s because they now have the correct information from the marketplace. Then we can do something about the 20% excess of goods that sit in the supply chain because we can’t get accurate information about what it is and where it is. Companies make way too much product every month because they aim to meet supposed demand rather than real demand from the marketplace. RFID provides the first real way to grasp the opportunity to recover that 20% because it has the most important aspect to it: OHIO, or Zero Human Intervention Operation.

PW: OHIO is crucial?

Greaves: Absolutely. It means much of the data collection can be done automatically and accurately. This is where packagers have enormous leverage, if they could fully enable RFID. That’s why packaging and packaging professionals are fundamental to the success of RFID in the consumer-products supply chain. It’s up to them to grasp the opportunity and seize the moment. Can you imagine returning to shareholders 20% of the current cost of holding inventory? Plus there’s more—consider that the cost of inventory is not just the cost of storing 40 pallets of finished goods in the warehouse, there are also 40 pallets of empty bottles and 40 pallets of corrugated to consider associated with that. We would not be hauling unrequired product. What we can do is produce to visibility. Today, most people order something because they can’t see they already have it on order. They don’t know its status. Although we have all this information today, the problem is we have no means to grasp that information and use it properly—because we can’t trust the data we have.

PW: What about item-level RFID, especially for high-value products?

Greaves: Let me save your readership a whole load of pain. RFID for item-level packaging in general will not come to pass until about 2010 using current technology. But even for Wal-Mart, with available technology, there is no possibility for an RFID tag on an individual Mars bar. But for the 48-count carton of Mars bars, that’s where your readership is immediately impacted. Exclusions to that rule include pharmaceuticals, consumer electronics, brown goods (TV, radios, cameras), white goods (refrigerators, etc.), tobacco products, and alcoholic beverages. I expect packagers of these products to be aggressively addressing an item-level RFID solution already. Because such products have a high selling price, it’s easier to justify the cost of item-level RFID.

PW: What about alcoholic beverages—what’s driving RFID in that market?

Greaves: Bottlers already have enough problems in the United States with state liquor control boards and they just don’t need any more constraints. RFID is a tool that can combat liquor sales to underage minors to the point that you don’t have it. With a wireless ID card and an RFID-tagged bottle, you can have clear evidence via a “handshake” between two electronic media. Of course, an infrastructure has to be built, but I believe that will come quickly.

PW: Aren’t liquids a problem for RFID?

Greaves: Well, that’s what the naysayers say, but that’s not entirely true. You can find a tag that will work with anything, but you won’t find a 25¢ RFID tag that works with liquid. Liquid has come to mean everything from Gatorade to gasoline, and there’s a big difference. For example, hydrocarbons such as motor oils are not subject to energy absorption, so they are transparent to RF waves. However, motor oil is packaged in plastic containers, which are a problem because they are strongly dielectric. That can lead towards deviation or dilution of the RF signal.

PW: Metals are also said to be problematic.

Greaves: It’s a matter of what you’re trying to do. You can turn that to your advantage by making the metallic structure part of the antenna. We are working on several projects right now that, well, are proprietary. . . but there are all sorts of defeat models if you want to be defeated. When it comes to RFID, my motto is this: Don’t bleat, compete.

PW: What about “slap-and-ship” RFID?

Greaves: The current slap-and-ship approach, as it has been called, is not sustainable. That’s because the temporary nature of the solution cannot be manually upgraded. As the volume of tagged shipments increases, so does the labor demand until eventually the labor costs are even greater than the tag costs. This is a step backwards and defies OHIO principles.

PW: What about metallic inks used as printed RFID antenna tags?

Greaves: Those will eventually be viable, but not right now.

PW: What’s the role of Electronic Article Surveillance technology?

Greaves: I think EAS is likely the first casualty of RFID. One only has to look at the efforts of EAS vendors to convert to RFID.

PW: What advice do you have for packaging engineers that are specifying RFID systems?

Greaves: They should keep in mind that currently it takes up to 0.7 seconds to write 128 bits to an RFID tag.

PW: Does that mean you must daisy-chain several readers together if line speeds exceed about 75 containers/min?

Greaves: Yes. But then you must also allow enough distance—roughly three feet—between the readers so they don’t write over each other. Otherwise, you’ll end up writing nothing for nobody. There are many subtleties to the installation of RFID at the point of production, order assembly, or dispatch. This is just one of them that requires extraordinary patience and diligence to minimize cost and maximize performance.

PW: As companies roll out with RFID, should they separate RFID-enabled packages in their warehouses?

Greaves: There’s no point in segregating nontagged and tagged inventory. It’s just another challenge in the supply chain for them. The best approach is to look for an all-tagged value model that provides at least cover costs, if not an actual cost reduction, across the entire packaged enterprise.

PW: What about RFID standardization?

Greaves: There will be no such thing as a tag standard, because there’s no such thing as a standard tag. How could there be? The tag that you put on this case here will not work on that pallet over there.

PW: Are there any other myths that you’d like to debunk?

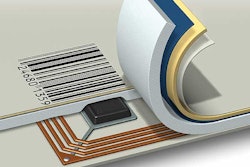

Greaves: Speaking of tags, most of your readers think a tag is a tag when they receive a shipment of 50 tags to test. But a tag consists of a chip, antenna, and a substrate that turns it into a “form factor.” They need to know that, and that all tags are not created equal. The tag is selected for the packager’s application. I know of 512-k memory tags in Italy that are a storyboard—meaning the entire shipment and product detail is written to the tag rather than a look-up table reference like an Electronic Product Code (EPC). Yet it appears the same to the human eye as a 96-k tag.

PW: What’s the current biggest challenge to RFID deployment?

Greaves: The challenge in the United States is that we have tended towards a corporate culture where initiatives are not permitted, and a business environment where corporate risk is discouraged. It’s only been recently that we’ve seen undue focus on quarterly returns and profits. When no one does a one-year-outlook anymore, how can you justify an investment in something like RFID, when the payback isn’t likely to come for many months?

PW: What’s the next biggest challenge?

Greaves: The problem right now is that manufacturers are growing tired of having to absorb another cost in order to have their product on Wal-Mart’s shelves. RFID should not be viewed as a cost; it’s a valuable tool if you take the time to deploy it optimally, both internally and externally. Isn’t it actually about improved supply-chain efficiency rather than about data? Yet, at end of the day, all that data isn’t worth a lick if the proper people don’t have access to the same data. Again, it comes down to data synchronization.

PW: What’s ahead for 2005?

Greaves: The reality is that there were no budgets created for RFID for 2004. This coming year will be the first one where we will see real budgets applied to RFID by corporations both big and small. Managers are preparing budgets now to give them the capital they need to finish this job.

John Greaves can be reached at 312/374-3463 or [email protected].