This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

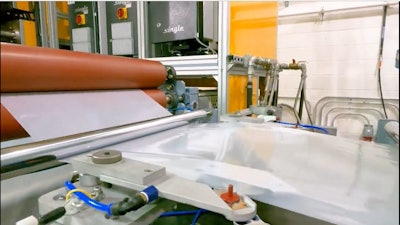

Following a multi-million-dollar investment, the new facility in Neenah, Wisc., offers R&D services and toll compounding for customers interested in developing flexible polyethylene (PE) packaging based on Void’s patented VO+ technology.

VO+ engineers nano- and micro-scale air pockets into plastics to create high-performance products with a lower environmental impact. It is effective in a range of thermoplastics including polyolefins and polyesters. The technology is most developed in white Machine Direction Orientation (MDO) PE films. By combining the benefits of MDO with VO+ cavitation technology, products can achieve:

• Material reduction: Lower density and downgauging

• Enhanced performance: Improved puncture, toughness, and high opacity without TiO2

• Improved recycling: VO+ white films turn clear during recycling because they are free of pigments like TiO2

With the official opening of the site, Void has launched VOID Labs, an R&D Services business through which plastics, packaging, and consumer goods companies can access the company’s start-of-the-art equipment. That includes pilot-scale blown film extrusion with inline MDO, lab- and commercial-scale twin screw compounding, as well as a range of testing and analytical equipment.

“Void is combining VO+ plastic reduction technology with R&D Services to help manufacturers and brand owners accelerate their commercialization programs for MDO PE films and flexible packaging. VO+ MDO PE films allow companies to reduce their plastic footprint by addressing the tension between material reduction, performance and recyclability,” said Void CEO James Gibson.