With growing attention on the problem of plastic waste, there is heightened demand for more eco-friendly packaging. Numerous global companies are taking measures toward targets for better circulation of containers and packaging, and efforts to drive recycling by adopting mono-material structures are gaining momentum around the world. Schemes for the recovery and recycling of polyethylene are starting to be seen in the U.S., and polypropylene is regarded as a recyclable material in Europe and other regions. In a PACK EXPO Connects demo, David Derfler, Sales Manager at Toppan USA, Inc. (Toppan USA), demonstrated how the company is responding to these trends by driving the shift to mono-material functional packaging.

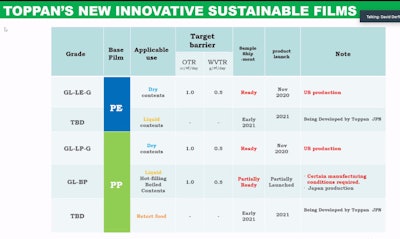

Toppan USA, a subsidiary of Toppan Printing (Toppan), announced that it has completed preparations for the production and supply of PE- and BOPP-based additions to its series of GL BARRIER transparent vapor-deposited barrier films. Full-scale sales of PE-based “GL-LE-G” and BOPP-based “GL-LP-G” launched this month, initially for the U.S. and European markets. Toppan can now offer GL BARRIER films with PET, PE, and BOPP substrates to facilitate a full range of functional, mono-material packaging. According to Toppan USA, samples of GL-LE-G and GL-LP-G have been made available to selected customers around the world since late 2019 under the provisional names GL-X-LE and GL-X-LP-G, and extensive assessments have been conducted to confirm their performance and market viability. Says Toppan, with GL-LE-G, the company has employed its advanced processing technology to overcome the difficulty of vapor deposition on PE and has created the world’s first transparent vapor-deposited barrier film with a PE substrate.