Bottled water continues to take a beating in the media, with reports targeting its environmental impact all the way from delivering the water from its source to the plant, through manufacturing and shipping operations, and to consumer disposal, littering, land-filling and recycling. That makes it refreshing to learn of companies moving to lighter-weight bottles, or to bottles made of biodegradable materials.

Taking the light-weighting approach is Nestlé Waters North America. The Greenwich, CT, company is rolling out its 12.5-g Eco-shape bottle across several of its bottled water brands (see photos A and B) this year, saying it’s about 30-percent lighter than average competitive 1⁄2-L plastic containers. Lighter still is Sidel’s (www.sidel.com) 9.9-g PET 500-mL NoBottle (C), which at press time was not yet on the market commercially.

Using the biodegradable approach is London-based Belu Natural Mineral Water, which is selling mineral waters in bottles (D and E) made of corn-based PLA from NatureWorks (www.natureworksllc.com), the material Biota Brands of America used for water bottles (F) it introduced (see www.packworld.com/view-18367).

Ozarka, Arrowhead lead Nestlé launch Much of the water-bottle backlash poured out earlier this year, with a flood of negative media reports following announcements by the mayors of San Francisco and Salt Lake City that they were banning bottled water in some areas of their cities.

At about that same time, Nestlé Waters North America launched its Eco-shape bottle under the Ozarka Natural Spring Water and Arrowhead Mountain Spring Water brands in different geographic markets within the United States. Throughout this year, the company will roll out the Eco-shape bottle for its Poland Spring, Zephyrhills, Deer Park, Ice Mountain, and Nestlé Pure Life offerings.

Joe Juliano, the group marketing manager of innovation with Nestlé Waters North America, explains that most Nestlé waters are filled into PET bottles, but the company also uses glass and HDPE. Sizes range from 8 oz to 1.5 L. Nestlé also sells 3- and 5-gal jugs for home and office dispensers.

“For a couple of years now, we have been looking to upgrade our packaging,” says Juliano. “We felt that the look of our bottles was old and outdated. We wanted to try to come up with a new, contemporary look for our brands that would appeal to consumers and deliver a premium [image]. By the same token, we were also trying to figure out ways to reduce waste and do something good for the environment.” Juliano says that Nestlé’s previous PET bottles weighed in, on average, at 14.75 g, which he says was still lighter than most competitive water bottles.

Juliano says that Nestlé injection/stretch blow-molds the Eco-shape bottles at several of its facilities nationwide. Captive bottle manufacturing and filling, he says, helps Nestlé to be “as efficient as possible.” The process means Nestlé does not have to ship bottles from a molding site to a plant that fills them. That said, Juliano admits that the Eco-shape bottle required “an investment of a lot of capital to make the project work. In addition to new molds, there were new changeparts required for many different machines, in addition to new injection-molding equipment.

“I would say this is probably the most difficult project that we have ever encountered,” he continues, “so hats-off to our engineering team because they really delivered.”

Juliano also says the paper label used for this bottle uses about 40-percent less material than its predecessor, creating economic and environmental advantages. Preferring not to divulge vendors, he says there are a couple of different suppliers of the labels. Some Nestlé facilities receive labels roll-fed, while others receive them cut-and-stacked.

Using less PET for the Eco-shape bottle and a smaller paper label would seemingly result in economic savings for Nestlé, but Juliano points out there there are other factors in determining costs. “You have to look at the rise in commodity [prices] in the last couple of years, in addition to the price pressures of the bottled water category. I would say that our organization would save a lot of money if commodities went down and if the average price of bottled water increased, but the fact is that commodities are growing, and prices are declining, so we are at a neutral state,” in terms of economics, he explains.

The Eco-shape bottle is designed with a pinched waist so that both males and females can hold it comfortably and carry it with them. Nestlé sells Eco-shape bottles in multipacks and in singles. “I would say that the majority of the business is in multipacks,” Juliano says, “with consumers tending to break open the multipacks and use their bottles for on-the-go consumption. Consumption outside the home is growing in relation to in-the-home consumption.”

Juliano says the Eco-shape bottles are sold at Wal-Mart, but notes that whether or not there is a scorecard, Nestlé is always going to try to do the right thing from an environmental prospective. “I haven’t spoken with anyone from Wal-Mart directly, but what I have heard from the field is that they are very happy with the bottle. We consider them a partner, and we will continue to look for ways to be more efficient and more environmentally friendly,” he says.

The Eco-shape bottle, Juliano says, “feels a little crinkly, if you will.” He adds, “We explained to [consumer focus groups] that the reason why is because we took out plastic, so we’re using less material and less fossil fuel to make and ship bottles. They felt good about that.”

Ozarka Natural Spring Water in a 24-pack has average retail price of $4.99, with six-packs sold at $2.49. Twelve, 28-, and 35-count packs are also available in select markets.

“This Eco-shape bottle is just the first step of a long vision of ways to be more environmentally friendly,” says Juliano. “We are looking at packaging for our whole supply chain. We are looking at secondary packaging, bottles, caps, labels, corrugated, and every facet of the way we transport water.”

Light-weight bottle development.

Meanwhile, Sylvie Ory, Sidel’s public relations leader in France, says that the NoBottle has generated interest from several bottled water marketers. Designed to contain 500-mL of water, the bottle is expected by Ory to be on the market by early 2008 at the latest. The bottles have a supple feel, more like that of a pouch.

Sidel designs the bottle mold, which customers would use to blow-mold the bottles. Sidel’s Flex technology, which combines bottle shape memory, is said to eliminate the need for ribs in the bottle. Ory says the shape memory allows bottles to withstand conveying, packing, transporting, and handling.

Asked about the NoBottle’s ability to provide barrier properties, Ory says that “the transmission of oxygen and water vapor is a little bit more important compared to standard PET containers, and this parameter is taken into account in the design of the bottle.”

Belu’s bio bottle for mineral water

While the Eco-shape bottle and NoBottle water containers focus on light-weighting, Belu Natural Mineral Water last year launched what its Web site touts as “the first corn-based, biodegradable bottle in the United Kingdom.” Bio-bottles are available in 500-mL singles and six-packs.

Belu says the bottle biodegrades under a combination of high heat, humidity, and microorganisms. The company’s Web site notes, “As long as bio-bottles make up less than 1-percent of all plastics, they won’t affect the quality of recycled products. In addition, roughly 10 percent of recycling centers in the U.K. have machines that can sort bio-bottles from PET and HDPE bottles. With landfill taxes rising, we expect the rest to be installing them soon, too.”

Regarding the recycling issue, Belu’s Web site says, “What will further hasten waste companies to sort bio-bottles is if it makes them money. … As with any innovation, the bio-bottle represents the first step on a journey. Just as there was no recycling system in place for PET when it was introduced 30 years ago, bio-bottles are slightly ahead of [their] time. But there is no question that this journey is worth it. We have endured over 75 years of toxic plastic pollution, and the end is nearly in sight.” At press time, a Belu representative was unavailable to provide additional details.

What about Biota? Telluride, CO-based Biota Brands of America Inc. made waves when it introduced bottled water in the United States in NatureWorks’ PLA. Biota, along with its sister company, Planet Friendly Products, developed what it called the “world’s first biodegradable bottle” as a means of “helping to solve the world’s plastic bottle problem.”

The corn-based bottle was designed to degrade within 75 to 80 days in commercial composting.

However, the company was not able to produce any water this summer due to its Chapter 11 bankruptcy status. However, in a phone interview with Packaging World, Biota CEO/Chairman David M. Zutler indicated that he anticipated production to start up at the company’s Ouray, CO, manufacturing facility by late October. Zutler says Biota will continue to mold bottles from PLA on its Blowmax Series III stretch/blow-molding equipment from SIG (www.sig.biz.com). Filling will be completed on a rotary filling machine from Fogg Filler (www.foggfiller.com).

How successful these light-weighted or biodegradable bottles fare on the commercial market remains to be seen. It’s understandable that these bottle introductions may not be driven purely by environmental goodwill, but also by marketing strategies aimed at generating “green appeal,” even if such tactics add costs.

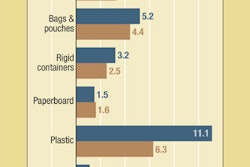

As the charts accompanying this story show, bottled water sales have soared in recent years, to the point where they’re competitive with more traditional beverages. As consumers continue to purchase bottled water, that market will continue to grow—and provide plenty of opportunities for packagers as well as suppliers of packaging material and machinery. The packaging community can watch for more “environmentally friendly” water packages as we move downstream.

–Jim Butschli, Features Editor