Seal replacement is fast, inexpensive, and may be completed in-house by the customer.

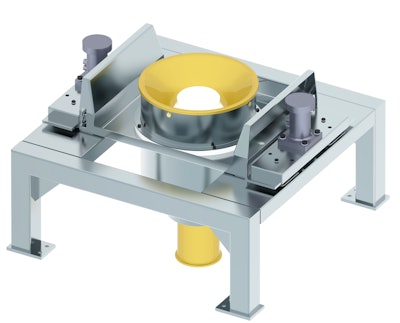

The ISL system

The accuracy of the ISL systems ensures batch accountability and consistency.

ISL’s filling station incorporates a cyclonic design that minimizes dust contamination of the environment.

ISL’s elegant engineering has simplified the design of the discharge system, utilizing 15 components. No tools are required for connection between the IBC and Discharge Station. Complete disassembly takes less than 10 minutes. The lifting mechanism in the Discharge Station is isolated from the product flow area, removing the possibility of product contamination. A low-pressure air supply elevates the cone valve into the IBC, while a position sensor provides precise flow rate control to accommodate all variants of materials. The simplicity of the engineering translates to minimal downtime for cleaning and maintenance.

ISL’s offers an in-bin blending system as a component of a complete product handling system.

The target market

The ISL solids and powder handling systems suit a wide range of customers. Typically large manufacturers with older, conventional processing systems seek ISL’s Intermediate Bulk Container systems to solve ingredient segregation and handling issues. Medium scale manufacturers utilise ISL’s systems to ensure higher levels of quality control for batch manufacturing. Small manufacturers benefit from the flexibility, scalability and cost efficiency of the ISL system.

Operational advantages

IBC systems offer manufacturers the flexibility to select any sequence of process steps.

Change of product lines or ingredients can be achieved quickly without loss of days or weeks typically needed for cleaning and reinstatement of conventional equipment. IBC’s reduce human interaction with the manufacturing process, exchange and removal of containers and discharge stations is quick and uncomplicated.

Cone Valve IBC’s require minimal maintenance and replacement of parts can be executed quickly with lower costs than other systems.

IBC’s enable the discharge of solids and powders with greater control, removing the risk of typical flow control problems including segregation and degradation. IBC’s maintain a high-degree of containment and batch integrity throughout the entire process chain.