Two lines at Unilever U.S.’s Baltimore, MD, plant prove that mass-flow filling equals efficiency squared. Also, communications on the lines equate to a highly positive subtraction: Off-board controls and networks saved hundreds of thousands of dollars (see sidebar).

In December 2000, the plant inaugurated the first of the new lines for its Liquids Operations. The goal was to achieve a 25% increase in daily output to satisfy sales growth. The products run on the lines include laundry detergent brands Surf, Wisk, and All in sizes of 100, 200, and 300 oz.

Unilever found that the first line can produce 25% more cases of product per eight-hour shift. That’s a record-breaking pace at the plant.

One good line deserved another, and so 18 months later, this summer Unilever started up a virtual duplicate of that line. For both lines, the major equipment was supplied through divisions of Barry-Wehmiller (St. Louis, MO). The centerpiece of the line is a monoblock filler/capper from Pneumatic Scale (Cuyahoga Falls, OH), the first mass-flow filler from the company. Before and after the filler, respectively, are a rotary uncaser and rotary case packer, both from Zepf (Clearwater, FL).

The first line has been full out on 300-oz F-style high-density polyethylene bottles since the start up, according to Unilever’s Cal Soper, who oversees plant TPM (Total Productive Manufacturing) operations that include these projects. Other members of the project team include plant engineering manager Mike Green, senior controls engineer Ted Angil, and senior packaging systems engineer Mike Massimini, among others.

The line’s layout allows for operation by one operator versus the two operators that are typically required, according to Soper. Notably, changeover on the line is entirely tool-less. “It’s all quick-change, quick-maintenance,” says Soper. “Before, a changeover required four hours and four mechanics. Now we can do it with one operator and one other person in one to two hours without tools.” Change parts allow the new line to be changed over between all three sizes.

Depending on the bottle size, reshippers arrive packed with two or four bottles per case. With the 300-oz size, the cases are a 1 x 2 pattern. The mechanically operated IAC Model 900 Uncaser from Zepf uses continuous-motion, pick-and-place gripper heads to transfer all the bottles at once from the case onto a conveyor. The gripper heads tighten around the necks of the bottles and lift them as a group. The bottles are deposited on an outbound conveyor that leads toward the filler some 40’ away. Cases are conveyed to the case packer.

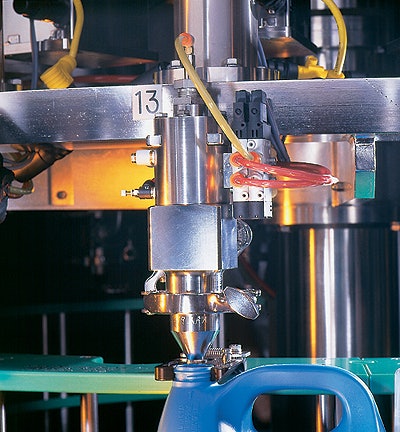

The monobloc filler is an 18-head mass-flow rotary filler integrated with a six-station capper. “We were looking for speed and accuracy and decreased time between product runs,” notes Soper. “We also did not want to shut down for line lubrication, and we wanted tool-less changeovers and maintenance.”

After an ultrasonic sensor confirms a bottle’s presence, the fill cycle begins. The pressurized product is supplied through fill tubes positioned about 1/8’’ above the tops of the bottles, which rest on stationary platforms.

“A mass-flow meter determines exactly how much product goes into a bottle,” explains Soper. “Each fill meter also adjusts continuously in real time to product conditions such as density and temperature. Giveaway on the 300-oz size is minimal, only a few grams.” Soper pegs overall accuracy within ±.2%. “Because filling is done via product mass rather than volume, bottle variances have no effect,” he adds.

The mass-flow meter’s design, along with Unilever’s networking, facilitates data collection that is accessed through a recipe-driven operator interface.

Soper points out that only three different detergent brands are run, though there are nine variations. That is why efficient changeover and washout cleaning of the equipment between production runs is crucial.

“Clean-in-place with the mass-flow design is a straight-through shot,” notes Soper. “We went from a two-hour washout on other lines to 15 minutes on this line. That is a big key to the line’s success.”

Filled containers transfer via starwheel to the integrated six-head cam-operated capper.

Soft landing = mass reduction

Casing follows, done by a “soft release” Zepf 9000 Series rotary packer. The mechanical system releases the bottles into the case from a height of less than ½’’ from the bottom of the case. “A conventional case packer has about a 22 inch drop, so this is really no drop at all,” Soper points out. As a direct result, his team will be meeting with the company’s blow molders to reduce bottle weights on the new line by around 20%.

The mechanical unit uses customized gripping heads to pick up the containers. The pneumatic, mechanical-loaded plastic grippers tighten around the handle, much in the same way as a hand would. Meanwhile, the opposite side of the machine accepts empty cases that are grouped and timed. The 300-oz bottles are deposited as a group back into the two-count case.

“The first line has exceeded its scheduled rate,” says Soper. “The efficiency is outstanding. With the start up of the second line, these two lines are without a doubt the best performing lines at the plant.”

See sidebar to this article: Controls clean up on savings