When bottles are shaken, this fusion of premium vodka, Moscato wine, and natural fruit flavors visually sparkles. The product’s success has since warranted national distribution. Roll-out began in February 2015.

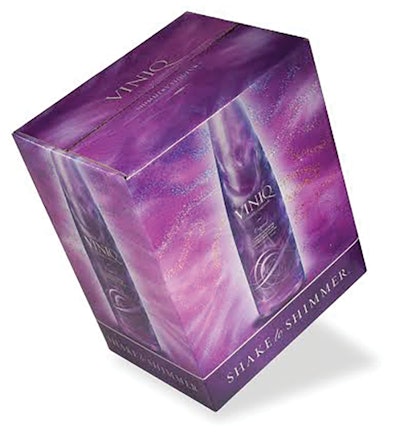

The vintner wanted unique display box packaging to reflect the shimmering properties of the bottled product. Gallo shopped around and decided to work with Pacific Southwest Container LLC and use Micro Glitter foil from the API Group, a leading manufacturer and distributor of foils, laminations, and holographic materials, to develop distinctive, high-shelf-impact corrugated cartons for the liqueur bottles. The B-flute corrugated cartons are lithographically printed with a four-color process and incorporate a non-skid UV gloss coating.

The sheet-fed operation involves five passes: First pass is the foil stamp; Second pass is 4CP print and UV coat; Third pass converts the sheet to B-flute corrugated; Fourth pass is die cutting; Fifth pass is folding and gluing.

Carton graphics were specially designed to complement the impact of the Micro Glitter foil. The result is the illusion of swirling, sparkling waves of light that emanate from the packaging, helping the carton to act like a “second skin” that communicates and reinforces the shimmering qualities of the Viniq® bottled product inside the carton.

Pacific Southwest Container uses a Model 126 BMA foil press from Bobst to apply the API Micro Glitter Foil to the sheet before overprinting with the high-impact graphics and the overall UV gloss coating. David Turnbaugh, Estimator at PSC, notes, “The selling point of the API Micro Glitter foil was the unique dot size and density and how great it looked with Gallo’s graphics. It has performed exceptionally well during manufacture.”