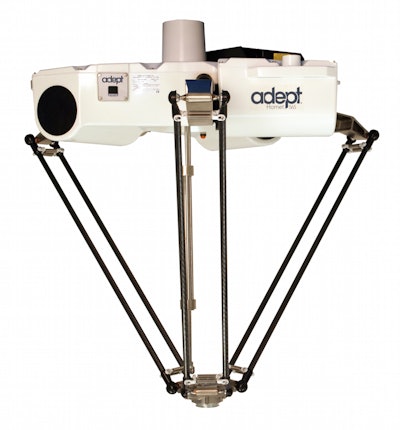

Adept Technology Inc. has introduced the Hornet 565, a new parallel robot with a 6.6-lb payload capacity. Featuring high-speed pick-and-place capabilities, the Hornet 565 offers ease of deployment and advanced performance suitable for packaging applications.

Adept’s controls are fully embedded into the base of the robot, saving valuable floor space and reducing installation costs and complexity. The Hornet 565 features a hygienic design that minimizes contamination risks, including a standard IP65 rating and corrosion-resistant materials for easy washdown.

The Hornet is part of Adept’s complete robotic packaging line that includes integrated high-speed conveyor tracking, powerful vision guidance, and easy-to-use application software created specifically for the packaging market. The robot can also be programmed directly from a PLC, minimizing training and deployment time by using familiar ladder logic programming languages.