This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

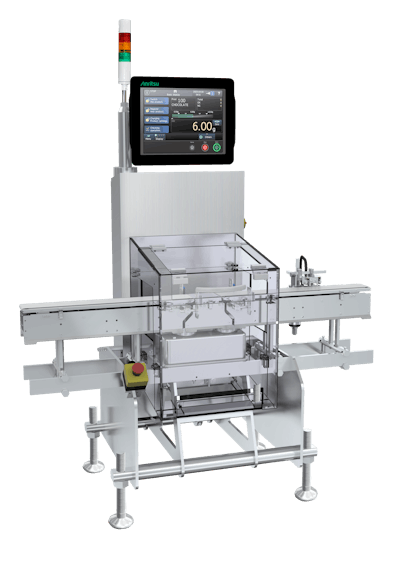

With over 50 years of expertise in precision weighing technology, Anritsu proudly unveils the new AW9 Series Ultra-Fast Checkweigher at PACK EXPO International 2024 in Booth N-4725. Designed to optimize high-speed production lines, the AW9 offers an impressive throughput of up to 1,000 products per minute while maintaining exceptional accuracy.

This innovation minimizes the impact of conveyor vibrations on weighing performance, thanks to three key advancements:

- Advanced Vibration Control Technology: Tailored to counter each conveyor’s unique vibration profile, ensuring unmatched stability and precision.

- Redesigned Frame Structure and Center Balance Layout: Isolates the checkweigher from external vibrations caused by surrounding equipment and its own conveyor, ensuring smooth, uninterrupted operation.

- Next-Generation Digital Force Balance Cell: Delivers precise measurements with an impressive accuracy of ±0.006 g, even at high speeds.

Anritsu’s XR75 DualX+ X-Ray Inspection SystemAnritsu

Anritsu’s XR75 DualX+ X-Ray Inspection SystemAnritsu

Superior performance is required to meet the high demands for food safety in today’s production environment. At PACK EXPO, Anritsu also is demonstrating its highest performing X-ray system to date, the DualX+ model, designed to tackle a long-standing challenge for food manufacturers: detecting the smallest metal contaminants and low-density foreign material such as bone and stone.

DualX technology uses both high- and low-energy X-ray signals, which Anritsu’s proprietary algorithms convert into clearer images, making it easier to detect low-density contaminants and reduce false rejects. The DualX+ model excels in challenging applications, such as overlapping processed meat products, loose products such as granola, and products with highly uneven surfaces. Also, provides improved detection in thick products.