This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

At its booth, Syntegon presented two SVX variants, which will be launched this year along two other SVX models. The SVX Agile forms the basis for all single tube applications. The machine covers all basic tubular bag styles and can be upgraded with modules for corner sealed bags, 3-sided seal bags, doy-style, and doy zip bags. In contrast, the SVX Duplex features two film lanes on the same 1,220 mm wide frame, leading to higher output rates for basic bag styles such as pillow, gusseted and block bottom bags.

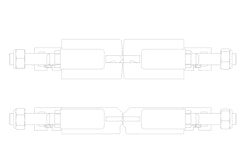

The core innovation of all SVX variants is a cross-seal drive consisting of four independently controlled servo motors. The optimized solution, which currently has pending patents, gives manufacturers full control over the vertical and horizontal movement, ensuring reliable seals. Due to a combination of four motors and low inertia, the drive contributes to achieving highest outputs.

When it comes to bag sizes, the SVX extends the range compared to previous machines: The series can produce bags that are up to 400 millimeters wide – providing full flexibility for both bag sizes and styles.

In terms of design and overall aesthetics, the SVX series also stands out: a front cylinder with curved sliding doors redefines machine manipulation and ease of access. Upon opening, the doors relocate to the back part of the cylinder, making sure they do not obstruct operators during the daily work. Moreover, the easily accessible film lane behind the cylinder offers enough space to install two printers.