The filler allows a lower initial investment, lower ceiling height requirements, smaller floor space requirements, and more manageable maintenance.

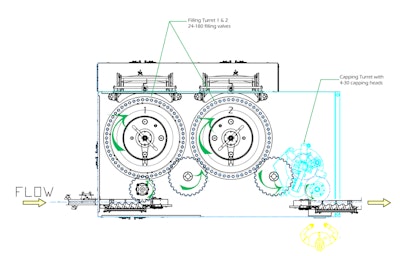

High capacity filling requirements of slow filling bottles (example: 28mm glass, 750ml wine or spirits), often end up with one very large filling bowl and a very large capper to match the geometry. The capper will run at about 50% capacity while the other 50% is wasted just because of the size requirements of the large filling bowl. To combat this capping capacity loss, Fogg provides twin smaller bowls that will fill faster than one big filling bowl while using 100% of the capper’s capacity at the same time. This change is said to save 10-40% in initial investment.

The twin filling bowls reduce waste rates by providing a combined maximum capacity of 340 gallons while large fillers can exceed a capacity of 400 gallons. This 15%-20% volume reduction helps maintain temperatures and flavor changes. There is also CIP savings as your system can be much smaller when you CIP two twin F6.2 bowls over one large one.

The twin bowl filler is about two feet narrower than a competitive single bowl machine layout, according to the company. It is also about four feet shorter.

Having twin filler bowls allows two operators to simultaneously work on the filler’s change over and maintenance. All the change parts are considerably smaller and more manageable, reducing maintenance.