1. Understand how the machine affects the product. You need to think about the impact of the filler on the product you’re packaging. The state or viscosity of the liquid can be inadvertently changed, based solely on the construction of the equipment. For example, running a liquid through extra elbows, pipes, and pumps can change the viscosity, resulting in a liquid that is much too thin. High speeds can also impact some products negatively. You need to keep the product characteristics front-of-mind when selecting equipment.

2. Understand how the product dictates the type of filler. The type of machine utilized for a project is often dependent on beverage/product characteristics and the type and shape of the containers. Free-flowing liquids like beverages work well with a timed-flow or overflow machine, whereas a more viscous product might be better suited for a piston or positive displacement (PD) filler. The fill size or type of container might also determine the type of machine used. Timed-flow and overflow machines are both good for free-flowing liquids but differ in how they deliver product to a container. Timed-flow fillers are a volumetric fill machine, meaning each fill cycle they deliver exactly the same volume of product. These machines are designed for very precise fills regardless of the container shape. However if the container varies in volume, the fill levels may have an inconsistent look. Glass bottles are a good example of containers that often have varying inner shapes and volumes.

3. Know the filling challenges of handling beverages with pulp or fruit pieces. Pulp or fruit pieces, otherwise known as particulates, require specialized pumps and valves based on the size and density of the individual particulates. Challenges with filling particulates arise whenever there is a significant variance in the size of the pieces. Pickles are a good example of a product that has particulates with a large size variance. Small or soft particulates are usually easier to accommodate.

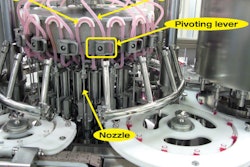

4. Look at ease of cleaning. Pay attention to the cleanability of equipment. As with any product destined for consumption, the machine must be made of FDA-approved sanitary materials. Most customers, including beverage providers, want equipment that is easy to clean and maintain. When filling bottles, keeping the nozzle clean is of primary importance to good manufacturing practices. Simpler design is better: Make sure the equipment doesn’t have nooks and crannies that can harbor microorganisms. Also look for filling machines that have clean-in-place systems as a standard feature.