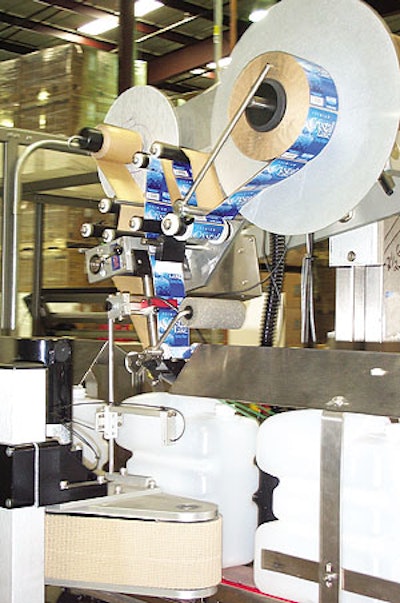

San Manuel’s line for 2.5-, 1-, and ½-gal HDPE bottles is every bit as versatile and automated as the PET line. Bags of bottles are debagged by a Dyco (www.dyco-inc.com) system that sends bottles single-file through a Quadrel Labeling Systems (www.quadrel.com) pressure-sensitive labeler. When the 2.5-gal bottles are being filled, labels are applied to a top panel. But with ½- and 1-gal bottles, the label must be applied to a side panel. The labeler’s sliding head permits this to be done with ease.

Immediately after labeling, bottles are conveyed into the same overpressured “clean room” that houses the filler used for PET bottles. A diverter sends bottles down one of two paths. The 2.5-gal bottles go through a six-head filler from Reid Plastics Group (www.cccllc.com) and a Reid capper that applies a plastic “spiggot.” A Fogg rotary filler/rotary capper is used for both 1- and ½-gal bottles. In this case the cap is a snap/screw type: The capper snaps it on over the neck finish’s threads, and consumers screw it on and off.