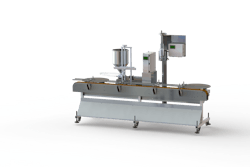

Packaging cream cheese is no easy task. Just ask J&L Food Specialties. The Glassboro, NJ-based manufacturer of flavored cream cheese spreads spent several years grappling with how to deal with the product’s high viscosity, which proved troublesome for its original packaging equipment. But those operational headaches are a thing of the past now that J&L uses the Waldner DOSOMAT, an automated rotary piston filling and sealing machine that provides consistent and reliable packaging of its cream cheese products by significantly increasing throughput, ensuring filling accuracy, and reducing downtime.

J&L produces about 750,000 lb of specialty cream cheese spreads annually as a co-packer and under its own brand. The family-owned company manufacturers 42 types of cream cheese spreads, including its popular Cajun Crab Dip, Cheddar with Horseradish, and Fire Roasted Red Pepper spreads, distributing them throughout the Midwest, East, and Southeast regions of the U.S. Over the last few years, the demand for J&L’s products has grown. In addition to buying the traditional 5-lb bulk tubs of the cream cheese spreads, J&L’s customers started requesting the products in 8-oz retail cups, too.

In a jam

In order to package its cream cheese spreads in 8-oz cups, J&L initially purchased a two-lane, in-line semi-automated piston filling machine in 2013. However, the thick consistency of the cold cream cheeses proved to be difficult for the equipment to handle. It often jammed or slowed down as a result of the product’s viscosity and cavitation in the piping of the equipment. As a result, the cups were often filled inaccurately, changeovers were difficult and time consuming, and the packaging process often came to a halt. Ultimately, the packaging equipment failed to deliver the necessary speed, flexibility, and efficiency J&L needed to meet customers’ orders.

“We are packing probably the most difficult product there is to pack. Most cream cheese manufacturers will process their cream cheese and flavor it and package it hot in the cup,” says John Esh, owner and General Manager of J&L. “We are doing a cold fill, and our product is stiff. There’s a viscosity issue here. You can’t pump it. It won’t flow. But it’s not a solid either. It’s just paste, and it is the worst thing in the world to fill. Peanut butter is easier to fill than that.”

After struggling with this packaging equipment for a year, Esh began looking for a suitable replacement that could adeptly handle the cream cheeses’ high viscosity. In 2014 at the PACK EXPO International packaging trade show in Chicago, he came across PTI - Packaging Technologies & Inspection, the North American distributor for Waldner, a Germany-based manufacturer of fully automatic filling and sealing equipment. After Esh explained the challenges his packaging equipment faced with J&L’s products, PTI suggested he use the Waldner DOSOMAT to package the cream cheeses with efficiency.

Esh got to see the DOSOMAT system in action. Accompanied by Waldner Managing Director Karl Angele, Esh traveled to a cheese plant in Germany that uses this same equipment to package a product of similar viscosity and texture to J&L’s cream cheeses. He was impressed with how the DOSOMAT automatically packaged the products quickly and without any workers manning the equipment. “I couldn’t believe my eyes. There’s nobody here making sure the cups are dropping. There’s nobody here making sure the heat seals are being done properly. All the cups were going to a checkweigher, and they all weighed within the specified range,” Esh says. “This thing was just humming along, clicking away, cup after cup after cup. It was just perfect.”

Customizing efficiency

Esh ordered the DOSOMAT in 2017. It took nine months for Waldner to customize the equipment to J&L’s specifications. A two-lane, rotary DOSOMAT system was installed at J&L’s plant in April 2018, bringing speed, precision, and versatility to J&L’s packaging process.

J&L runs the DOSOMAT equipment twice a week. Workers manually load about 400 stacked polyethylene cups into the magazine, which can be refilled while the machine is operating. They then use a lift to pour 400 lb of cream cheese into the hopper. Vacuum grips place the cups in slats on a rotary table, which secures transport of the cups from station to station. An ultrasonic photocell sensor verifies the presence of the cups. If a cup is missing from one of the slats, the machine stops and alerts the operator via the HMI.

The dosing system features a piston pump that draws the product out of the hopper via a rotary valve into a dosing cylinder. Once the cylinder is full, the rotary valve flips 90 deg. The piston then pushes the product through the rotary valve into the discharge tube, which dispenses the cream cheese into the 8-oz containers. Because the volume of the cylinder doesn’t change from fill cycle to fill cycle, the same volume of product enters and exits with the piston on each stroke, ensuring a highly accurate volumetric fill.

The filled cups then move to the cutting station. The manifold houses cutters that remove any food strings attached to the rims of the containers to create a clean surface for sealing. At the sealing station, a sealing bar heat-seals rollstock lidding film to the cups. In the same motion, integrated film-cutting knives remove the excess film from the cups. The cups then enter the capping station, where overcaps are mechanically placed onto the sealed cups. Vacuum grips lift the cups out of the rotary table and place them on a conveyor belt for secondary packaging.

Gaining the advantage

Since J&L began using the DOSOMAT, the company has been able to improve filling accuracy and minimize product loss, according to Esh. “We are able to run our weights at a much closer tolerance, which saves us 0.02 pound per cup,” he says. “If we run 10,000 cups per day, we have a cost savings of $300 per day, or well over $75,000 per year.”

Esh attributes the product and cost savings to the DOSOMAT’s rotary valve system. Because the valve in the DOSOMAT transfers the cream cheese directly from the cylinder to the dispensing tube, there are no opportunities to create cavitation, where product and air can build up.

Changeover is also a breeze now with the DOSOMAT equipment, taking only about 10 minutes to prepare it for the next product. Operators simply purge, wash down, and sanitize the fill station section of the equipment. Then they select the appropriate recipe stored in the HMI. Based on the recipe chosen, the PLC automatically adjusts components of the equipment to take into consideration the specific texture, particulates, and viscosity of the next cream cheese product to be packaged to ensure the DOSOMAT fills the cups accurately and quickly.

With the previous packaging machine, J&L workers spent at least 30 minutes preparing it for changeover. Not only did they have to wash it down, but they also had to manually adjust the length of the stroke of the piston with a limiter to accommodate variation in the product, including the addition of fruits, nuts, or vegetables as well as the texture. Then they ran a few test cups to determine if they had adjusted the piston correctly to dispense the correct weight of the product. If the weight was incorrect, then the operators had to readjust the piston until it filled the cups accurately. This trial-and-error process resulted in product loss and downtime.

While Esh appreciates the reduction in downtime and product lost and the improvement in filling accuracy, he is also pleased that the DOSOMAT uses servo technology from Schneider Electric Elau and Allen-Bradley, ensuring the machine runs smoothly and precisely and produces maximum output. The DOSOMAT packages about 75 cups/min, while the previous equipment J&L used only produced about 30/min due to the downtime it consistently experienced, according to Esh. “We’re running the DOSOMAT at about 60 percent of its capacity as far as speed,” he says. “But this will easily do about 75 cups a minute, which is extremely fast for a small company like ours.”

Now that the DOSOMAT system has helped optimize its packaging operations, J&L plans to use it to grow its business by selling more of its cream cheese spreads in 8-oz retail cups. “While the machine did cost more than what we expected to pay initially, its speed and precision have changed the packaging side of our business completely,” Esh says. “It was well worth it. Now we are able to complete our orders, meet our deadlines, and look for new business. We are confident that when we start up this machine, we’re going to have a successful run.”