Click here to download this article in PDF form

Before they are consumed as fresh or frozen drinks fruit juices isotonic beverages and teas are very often packaged while hot. Hot filling actually eliminates the microorganisms that threaten both product quality and consumer safety. Long the exclusive domain of the glass bottle these drinks are more and more frequently found in PET bottles. The containers are lighter tougher and better suited to today’s on-to-go consumption.

Some powerful technology underlies this market growth. Starting at 60°C PET softens and loses its shape. Furthermore the package is subject to hydrostatic pressure exercised by the weight of the hot liquid on the walls. The container must then withstand conveying while it’s still hot. The neck must not become distorted during capping or when it comes in direct contact with the hot liquid. Finally the cooling phase that follows filling causes the liquid volume to shrink and generates vacuum inside the bottle. This is amplified by condensation of air in the head space. Given these obstacles a method must be found to considerably boost the package’s heat resistance to maintain its physical integrity.

Developing hot fill solutions is no easy matter and implies a keen knowledge of the properties of PET material.

PET – In all its Forms

PET is a semi-crystalline thermoplastic. Depending on its transformation state PET can be found in a totally “amorphous” or a “semi-crystalline” form. In the latter case its morphology is comprised of amorphous and crystallized phases. In its amorphous state PET’s molecular chains are not organized sort of like a big ball of yarn. Conversely in its crystallized state PET’s molecular structure is a dense and organized arrangement of molecular chains the origin of which is double.

Some crystals form due to spherulitic crystallization when heat is applied at around 150°C. When PET is not stretched crystals appear around impurities and catalytic residue. Spherulitic in shape these crystals develop a threedimensional structure composed of molecular chains folded over a nucleus. PET’s three transition temperatures They are relatively large (around 6 microns) compared to the wavelength of light. Thus they cause the material to lose its clarity. Some crystals develop due to induced crystallization when the molecular chains are subjected to mechanical stretching during bi-orientation blowing. When a certain orientation ratio is reached the molecular chains align according to directions of orientation that bring the nuclei close together. Links are created that lead to the formation of parallelepiped crystals. Their very small size (about 60 angstroms or 1 times smaller than the spherulitic crystals) doesn’t alter the material’s transparency. The structure obtained by stretching is 14 Blowing & Coating Blowing & Coating 15 similar to a weaving and it is much stronger than the amorphous structure. By modifying PET’s molecular structure spherulitic or induced crystallizations improve PET’s mechanical strength and thermostability.

In contrast the amorphous phase remains heat sensitive. Beyond a certain temperature it tends to resume its original shape due to the memory effect. Amorphous PET softens when it nears this glass transition temperature which is around 75°C. Bottles produced using traditional techniques tend to lose their shape starting at around 60°C which makes the containers unsuitable for hot fill applications.

Finally PET is hygroscopic meaning that it absorbs moisture from the air. At the molecular level water has a lubricating effect. Sidel has conducted studies that have shown that by taking a few simple precautions the effect of water absorption in preforms is negligible. In contrast the phenomenon can also occur during package aging and depending on the amount of water absorbed can reduce a container’s thermostability.

Special Design

One way to overcome these hot fill challenges is to define bottles with special designs.

Hot fill bottles have a structure that can withstand hydrostatic pressure. The bottles have absorbing panels to prevent deformation of the walls due to compression. Beams and belt keep bottles from becoming out of round. All of these special features create a package that is 25 to 30% heavier than conventional bottles.

The mostly amorphous neck is particularly sensitive to heat. Greater thickness is generally sufficient to withstand relatively low filling temperatures. But when these temperatures rise the neck must be thermally crystallized or must have a heat resistant plastic insert.

The optimized stretching reduces the amorphous part of the bottle base as much as possible. But it is hard to completely eliminate this amorphous part. Special design features such as ribs in the base compensate for the material’s reduced strength so that the package’s base retains its shape.

Heat setting

The primary goal of heat setting is to reduce the amorphous part of the bottle that may soften when heat is applied. For heat setting the crystallization ratio must be increased in order to raise the glass transition temperature so that it is now higher than the temperatures that occur during the packaging phases. This limits any deformations in the material at these temperatures.

The second objective is to relax the residual stresses on the molecular chains. Caused by mechanical strains during blowing these mechanical stresses become set in the material during cooling. If they have not already been “relieved” the residual stresses will eventually be “relieved” when heat is applied later with the high temperatures that accompany packaging. Then the molecular chains tend to resume their non-stress state which results in the bottle’s deformation. Thus heat setting must be done so that the stresses are relaxed prior to packaging.

Sidel’s HR and SRF Processes

Sidel has developed two processes that allow it to heat set bottles. The first process is Sidel’s HR technology used on Sidel’s standard SBO Series2 machines with some adaptations made to the oven and blowing wheel. This technology employs a modified reheating process for preforms with specific profiles. The process ensures that high quality bottles in compliance with design and material distribution specifications are produced during blowing. The process is an important part of heat setting. The induced crystallization is then developed using longitudinal stretching.

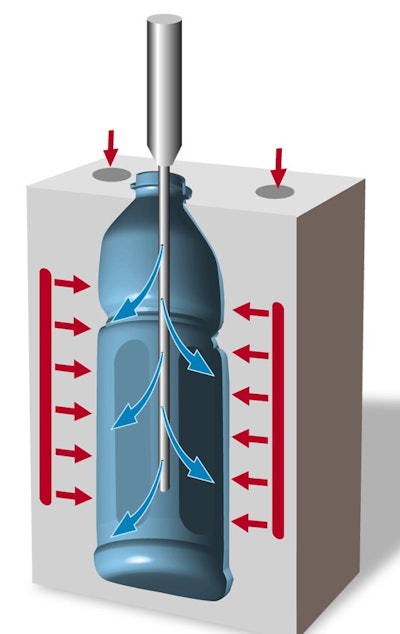

After blowing the bottle remains under pressure in the mold. During this stabilization phase the bottle walls are pressed against the molds that are kept at a high temperature. The heat allows some of the stresses to be relaxed by rearranging the molecular chains. The contact time is longer or shorter and the temperature is higher or lower depending on the level of heat setting required. This phase is a determining factor in output rate. It is followed by air injection inside the bottle using a flow of low-pressure air. The air injection stabilizes the bottle and causes its final shrinking at which point it disengages from the mold. The bottle is then transferred and leaves the blowing machine with no deformation.

The HR process is by far the most frequently used. It is a simple way to produce high-performance bottles that withstand temperatures of up to 88°C even under the most difficult conditions of aging with maximum water absorption. To achieve still better performance the internal stresses must be relaxed even further. It is possible to raise the temperature inside the molds even higher. However beyond 145°C the 17 lightweight molecular chains called oligomers leave deposits on the molds and alter the transparency of bottles. This requires frequent shutdowns to clean the molds and makes the solution industrially non-viable. Therefore Sidel has developed another process that allows it to further improve the performance of its heat set packages. The basic principle of this process involves eliminating the step of transforming a preform into a bottle because the dimensions are so vastly different and this causes significant stresses. So a three-step approach is used called the Blowing Reheating and Finishing (SRF) process. It’s used on a standard SBO machine that feeds a second oven that is then followed by a second blowing wheel. For this reason the process is called the “two wheel” technique.

The bottles blown using SRF processes have unique properties that allow them to withstand the highest temperatures up to 95°C even after aging.

See 5 bottle display of the rangle of solutions