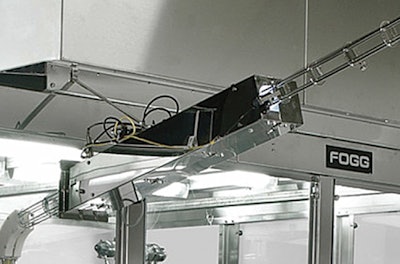

Caps are treated to a combination of chemical exposure and mechanical action. If the supply of product to be sanitized is interrupted, pneumatic escapements and photo-eyes monitor and toggle appropriately, so every unit is properly dosed. Process effectively removes loose debris such as corrugated dust, while allowing sanitization solution to contact all exposed surfaces of the cap.

Duration of exposure is variable and can be tailored to a specific application to achieve customer’s desired log reduction in microbial count. Rates of 1,000 caps/min are possible.

Phone: 616/786-3644 | www.foggfiller.com

Companies in this product