This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

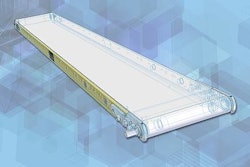

The heavy welded frame design is ideal for rough environments, while the conveyor is constructed to withstand the continuous impact from large containers and packages. Developed for ease of maintenance, the CS3600 Caseweigh™ features quick change belt replacement and convenient side access to critical electrical and mechanical parts such as those used for belt tracking and tensioning.

Custom widths, lengths, stainless steel construction, and hazardous area versions are also available. A Micromate® controller is standard with each CS3600 Caseweigh™; simple operation reduces operator training and line changeover requirements while delivering superior performance and value. The Hi-Speed CS3600 Caseweigh™ is available in three standard belt sizes and is capable of checkweighing uniform products or capturing the weights of random sized packages. Its high quality, heavy duty construction delivers accurate and reliable performance to meet even the most demanding of industrial applications. Custom sizes are available. An optional infeed conveyor can also be provided to create the necessary product spacing, while an optional discharge conveyor can be supplied for an integrated reject station to handle non-conforming packages.

The CS3600 Caseweigh™ is supplied as standard with the full featured Micromate® controller. The optional Micromate+™ adds a statistics program, alarms group, and enhanced reporting package to the system. A Checkmate® series controller is available for users who may require up to 150 product set-ups, multi-scale control, additional statistics capabilities, or enhanced control functionality such as filler feedback for single or multiple fill head applications