This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

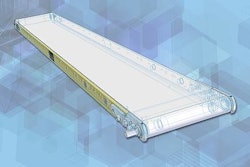

The system consists of a two-stage Smart Belt conveyor assembly, which instantaneously creates the appropriate spacing between random packages. The converge conveyor funnels each package into a single lane at the desired speed. All sequencing and product positioning is accomplished with high-performance servo motors, sensors, and controllers. Package damage and contamination is avoided, because no hardware is required to touch the package for positioning.

The Servo Smart Belt System can accept a wide variety of different package types of various dimensions and can operate at various speeds to meet the throughput requirements of your line. For example, a 9-inch tray with three lanes converging to one can flow through the system as fast as 120 ppm. Fewer lanes and shorter packages can result in higher rates. The System is designed for a washdown environment following USDA meat and poultry design guidelines. It includes a heavy-duty stainless steel frame and easy-to-clean, removable belts.