Putting a useful tool in the hands of customers is one of the biggest benefits in creating a Web site. According to Mark Garvey, president of conveyors and systems manufacturer Garvey Corp., Blue Anchor, NJ, that was the incentive behind the firm’s development of Thruput.com.

“The reason I set up the site is because I do outside consulting work on packaging production lines and how to increase their outputs,” says Garvey. “Those customers, along with Garvey customers, can use the site to understand what the impacts are by properly buffering a line.”

Garvey and associates have been using a mathematical algorithm since the late ’70s to identify the limiting machine in a packaging line. This calculation determines the most efficient place to install a conveyor that acts as a buffer in times when a machine fails.

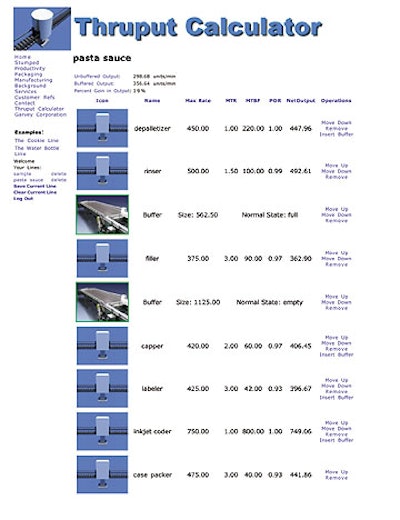

In November 2001, Garvey featured the Thruput Calculator, located on the left navigation bar on the Web site www.thruput.com. Registered users begin the calculation by typing in the maximum standard rate, mean time to repair, and the mean time between failures for each piece of machinery located on their packaging line.

With this information, the program identifies what the constraints are, determines where to place what size conveyors, and calculates the rate and percentage gained in output.

For example, a packaging line for pasta sauce that may include a depalletizer, bottle rinser, filler, capper, labeler, ink-jet coder, and case packer has an output rate of 299 bottles/min. After inputting the standard rate, average repair time, and average time between failures for each machine, the Thruput Calculator added a conveyor before and after the filler. In this example, it calculated a 19% gain in output with output being 357 bottle/min.

“It never ceases to amaze us how people aren’t aware of the effects these buffers can have on a packaging line,” says Garvey. “This is why we are offering this tool on the Internet.”