Producing a diverse range of generic prescription topical, injectable and ophthalmic pharmaceuticals, New Jersey, Toronto-based Teligent built their success on a culture of quality.

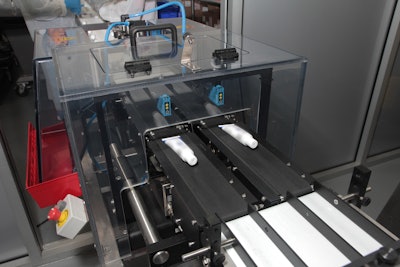

To automate inspection on their high-throughput tube line, they turned to Mettler-Toledo Hi-Speed and selected a customized XS1 checkweigher with a two-lane configuration that matches Teligent’s dual-lane filler. Detecting and rejecting under- and over-filled tubes, this checkweigher helps Teligent ensure final product quality and provides data to improve yields.

“Mettler-Toledo modified their standard one-lane XS1 to meet our line requirements, designing two lanes with a weigh cell under each one. By complementing our dual-lane filler, the machines were easy to integrate,” explains Mike Bertonazzi, Packaging Supervisor. “This checkweigher handles our high speeds in a small footprint with phenomenal accuracy.”

The XS1 cab achieve an accuracy of +/- 20 mg with a throughput of up to 400 packages/min by using advanced electromagnetic force restoration (EMFR) weigh cells, instead of common strain gauge load cells.

“We have very high standards at Teligent, and the accuracy of this checkweigher helps us meet those standards,” says Ehor Andrasz, Packaging Mechanic. “Laminate tubes don’t seal properly if they are overfilled, so we reject overfills as well as underfills. The system has two reject devices, one for each lane. We segregate rejected packages, which helps us ensure final product quality.”

Designed to handle small, lightweight packages of valuable products that weigh 200 g or less, the XS1 was installed at Teligent in 2015 to assist in automation. The line fills lotions, ointments and gels, primarily regulated pharmaceuticals for private-label customers, into metal, plastic or laminate tubes ranging in size from 2 g to 30 g.

“Because our Hi-Speed checkweigher captures real-time data, it enables us to be more proactive in monitoring fill weights, which helps improve our yields. The display is like an odometer that shows when tube weights are drifting,” explains Bertonazzi. “If there’s a fluctuation outside the target weight zone, we’re alerted in real time and can quickly make adjustments to the filler.”

Featuring a 15-in. color touchscreen, the XS1 has a “dashboard” layout with 23 separate fields for “at-a-glance” monitoring of the production process. Password protection offers three levels of access to prevent unintentional and unauthorized changes. “This checkweigher’s functionality and software allow us to streamline the changeover process,” says Bertonazzi. “The user interface is very intuitive.”

To track rejects and product fluctuations, Teligent has access to collect batch data from the XS1 via a print stick, with the capability to connect the system to the plant-wide network for more streamlined reporting in the future. Batch reports can be reviewed on batch-by-batch basis at Teligent to confirm that no irregularities have occurred on the production line and to analyze performance for improved overall equipment effectiveness.

“We choose Mettler-Toledo because they gave us everything we needed—reliable, easy-to-use equipment and superior service. Their reputation for producing great inspection systems matches our experience,” says Jason Edwards, Packaging Manager.

“Our sales rep, Joe Young at Reliant Packaging, really took the time to understand our needs. He helped us select the ideal checkweigher for our application by recommending a very customized dual-lane solution,” adds Al Wissler, Maintenance and Facilities Manager.

“We measure the success of this equipment by its accuracy. We have specific fill-weight requirements for each package that we absolutely must meet, and the XS1 is a very efficient tool to verify that each tube we produce is within our defined range,” notes Edwards. “This checkweigher helps us uphold our commitment to quality. It gives us confidence that every single product coming off the line meets our weight specifications.”

In July, Teligent announced a 75,000-plus sq-ft expansion of its manufacturing and R&D complex in Buena, NJ. Once completed, Teligent says on its website, “The expansion will include the installation of a new isolator-based sterile injectable manufacturing suite and will deliver a significant increase to the company’s manufacturing capacity for topical pharmaceutical products.”