Signs pointed to “yes” two years ago when Fred Marshall, automation engineer at Axxess Technologies, was considering replacing an aging shrink wrapping unit with more efficient equipment. The Tempe, AZ-based manufacturer of adhesive numbers and letters found what it was looking for at Pack Expo ’98, sponsored by the Packaging Machinery Manufacturers Institute (Arlington, VA).

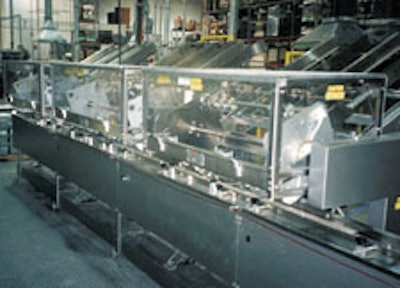

The machine that caught the eyes of Axxess engineers who attended Pack Expo was a Sasib (De Pere, WI) WM24 Widened Shrink Wrapping System, which they promptly purchased. That machine, in addition to a trio of Thiele (Minneapolis, MN) pick-and-place feeders, has helped Axxess increase its output by more than 50%.

Axxess Technologies makes and packages pressure-sensitive lettering and numbering products typically used for mailboxes and other home labeling projects. The letters and numbers come on sheets that are sold at mass merchandisers. The sheets are shrink-wrapped in varied quantities.

“The old machine was very frustrating to work,” Marshall says. It used a belt to feed the sheets on top of each other for packaging, and friction from the belt occasionally pulled an adhesive number or letter from its backing sheet and jammed the machine, says Marshall.

The new system uses vacuum pickup cups instead of sheet feeding to avoid friction and product damage. Axxess can now process 65 sheets/minute while the old unit could only process 30. Marshall says the new installation has made a “night-and-day difference.”

“It’s easier to set up and run, and easier to feed the film,” says Marshall. “And it’s much more reliable and faster, too.” The equipment wasn’t cheap, he adds, “But it has increased efficiency. You don’t have as much rework. You don’t have to feed the sheets through twice. And there’s no material to throw away because of a bad seal.”

Fewer shifts

Because the new machines run faster, Axxess was able to eliminate a work shift. There are currently two workers on the Axxess packaging line.

According to Wes Henriksen of Rainbow Packaging (Chandler, AZ), who helped integrate the machines for Axxess, there are three rotary pick-and-place feeders synchronized with the Sasib wrapper. These feeders place sheets of product into the continuously moving flighted conveyor of the Sasib machine.

Rotary feeder number one has three pairs of vacuum pick-and-place pickup cups. Each pair is aligned with its own magazine feed, so with each 360° revolution, the rotary feeder picks from the magazines and places one paperboard backing sheet and two sheets of product onto the flighted conveyor.

Rotary feeder number two has the same three-magazine configuration, but all three magazines are fed with sheets of product. Finally, rotary feeder number three uses just two pairs of vacuum pickup cups and two magazines. The bottom line is that Axxess can load anywhere from two to seven sheets of product. Loading all available magazines creates neat stacks of seven sheets plus one backing board in each conveyor flight. Leaving some magazines empty results in fewer than seven sheets of product in a stack.

The stacked sheets move from the flighted conveyor to the infeed of the Sasib wrapper. The 50-ga polyvinyl chloride film from Reynolds Metals (Richmond, VA) is pulled off the roll by nip rollers and fed through the wrapper by a vacuum belt. As the film advances, it’s pulled over a former that folds and seals it into a tube shape. Product is conveyed to the cutting head where it is crimped, cut and heat-sealed, creating an end seal. Finally, a shrink tunnel shrinks the film tightly, and a hole is punched through the top for peg display in the store by an in-line, high-speed hole punch from Rainbow Packaging.

Marshall has been very pleased, not only with the machine’s success at Axxess Technologies, but also with the accommodation and support provided by the vendors. He says that Axxess had to pay for the machine in installments and that the vendors “were no problem to work with as far as payment.”

Marshall says he will attend Pack Expo International 2000 this fall in Chicago, again with an eye out for some printing applications he saw at Pack Expo Las Vegas. He says the show is an excellent opportunity to weigh his equipment options and to view new, innovative technology.