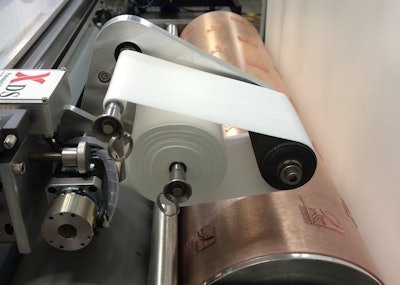

KleenPlate+ traverses the plate automatically during printing while removing dried ink, debris, and contaminants, using a lint-free cloth, from the plate's surface directly after the print nip. A 'kiss' contact and completely dry process make all this possible without compromising print reproduction or plate surface, whether solid or fine screen.

The head can also be removed from the rest of the system, when necessary, for cleaning and maintenance. A user-friendly interface enables multi-mode operation, flexibility, and precise control. The cleaning pressure against the printing plate is easily adjustable. Features include:

- Runs continuously with zero stoppages for plate cleaning

- Eliminates defects to print near-perfect solids

- More production run time

- Quick return on investment

- Significant waste reduction

- Minimized ink piling/plugging, bridging and drying on printing plates

- Substantial reduction in plate damage