Packaging World editors have begun to hear tell of packaging operations where wireless connectivity is being deployed. These three examples are worth a look.

The first, in pet food packaging, is at Nestlé Purina. That’s where Sentekin Can is part of a team that is about two years into a project that has added wireless Local Area Networking (WLAN) to existing wired Ethernet LAN in 22 plants across the country.

“Decisions on what wireless technology vendor to use were made jointly by the electrical engineering group and the information systems group,” says Can, principal controls engineer at Nestlé Purina and a member of the EE team. “Once the selection process was complete, installation responsibility went to EE.”

Can says the implementation of wireless, which is an IEEE-802.11g solution, has been very successful, though he chooses not to identify the key vendor. About 40 access points in each plant are mounted throughout the facility so that wireless signals can be sent wherever they need to go. Each access point has two radios, one compliant with 2.4 GHz IEEE 802.11 b/g and the other compliant with 5.6 GHz 802.11a. The latter, says Can, isn’t used currently but is there for future use.

Also installed are antennae—about 80 per plant—and switches. The antennae make accessible the wireless signals sent by the radio in the access points. The Power over Ethernet (PoE) layer 2 switches are the means by which access points and antennae connect to the WLAN.

According to Can, a key benefit is greatly improved handling of incoming raw materials and outgoing finished goods. Take finished goods, for example. Forklift drivers use a hand-held bar code scanner connected to a computer on the forklift truck. When this computer receives the information contained in the bar code scanned by the driver, it emits a wireless signal picked up by antennae throughout the plant. Then the information flows instantly to the Enterprise Resource Planning (ERP) system, which returns a signal to the forklift computer telling the driver exactly what bay or aisle or bin in the warehouse that pallet belongs in.

Can emphasizes that wireless in the warehouse is not what’s new. “We’ve had wireless in the warehouse for maybe 15 years. But it was a 900 MHz signal, and it wasn’t an open system so you couldn’t interface anything to it, like an ERP system, for example. The new system is 2.4 GHz. And now we have antennae not only in the warehouse but throughout manufacturing, including the packaging room.”

Can says that wireless hasn’t made its way into Nestlé Purina’s packaging machinery yet. But one part of the firm’s packaging operations that will soon go wireless is the handling of paperboard cartons. These are in corrugated shippers in the warehouse, the shippers are palletized, and on the pallet stretch wrap is a bar code label identifying the contents of the pallet. Suppose a forklift driver picks a pallet of green cartons for transfer to the packaging room. He’ll use a hand-held scanner to wirelessly update the ERP system that a pallet load of green cartons has been moved to packaging.

“Suppose half of those green cartons are set aside in the packaging room because the production schedule requires that the cartoning machine switch to red cartons,” says Can. “Again, that information will be scanned wirelessly into the ERP system so that inventory will always be up to date on a real-time basis. In the past, all that information was captured on paper. Not only was it time-consuming and more labor-intensive, inaccuracies were common.”

Can sees a day in the not-too-distant future when wired Ethernet connectivity between the plant floor and the ERP could become wireless. “If you don’t want to spend time and money on the conduit and wiring required for Ethernet, you may find wireless attractive,” he notes. “Machine-to-machine connectivity could also be wireless. Suppose I need to replace a metal detector in a packaging line. If the line is networked via an Ethernet cable, I encounter those cabling issues again if I want the new metal detector to be part of the network. But with a wireless system, the antennae are already in the ceiling. All I need to do is have the supplier of the metal detector deliver it with an integrated radio. That’s it.” All of these packaging-centric scenarios, says Can, will get a big boost forward when certain standards currently in development are finalized.

“Though packaging-specific wireless activity in our plants is modest right now,” Can continues, “the way has been paved. The antennae are already in the packaging room and our ERP system is in place. Bringing wireless functionality to our packaging machines would be pretty straightforward. Just put a wireless Ethernet card in the machines and do some programming. But there’d be no construction or laying of conduit required.”

Rotary filler leaves cables behind

The escape from cabling that comes with wireless technology was also a key driver behind a recent development at a major manufacturer operating a 16-station rotary powder filler. The manufacturer chooses not to be identified, but the application is a fascinating one that provides a glimpse of how wireless technology could transform packaging machinery in the near future.

The controls package on the 16-station rotary powder filler consists of 16 CompactLogix controllers, one for each net-weigh filling station, governed by a central ControLogix controller. Both CompactLogix and ControLogix controllers are from Rockwell (www.rockwell.com). As originally designed, an electrical slip ring was used to make the electromechanical connection allowing the ControLogix device to communicate with the 16 CompactLogix controllers. The slip ring consists of a conductive ring mounted on a shaft. Fixed contacts or brushes contact the ring, transferring the electrical signals. On this particular machine, the signals were conveyed via a wired Ethernet connection.

This arrangement held a few downsides. The slip rings cost about $20,000 each. And because they are mechanical in nature, they need to be replaced occasionally. Dropped packets of data were also a problem, requiring data re-transmission that consumed band width and generally clogged things up. Recognizing room for improvement, the manufacturer explored the possibility of replacing slip ring and wired Ethernet connectivity with ProSoft Technology (www.prosoft-technology.com) RadioLinx Industrial Hotspot Ethernet radios as a wireless solution. A total of 17 radios were involved, one at each filling station and one at the ControLogix controller. Data now flows wirelessly to and from the central controller and the remote controllers. Benefits include:

• Improved throughput because there are fewer dropped packets of data

• Reduced maintenance costs because slip rings no longer need to be maintained or occasionally replaced

• Less wiring

“The constant flexing and wiring in any rotary system causes lots of wear and tear,” says Lary Marshall of ProSoft Technology. “And when the wired connection failed, the machine stopped.”

The frequency used in this application is 5.8 GHz. “We worked closely with the customer’s IT people in determining which frequency range we wanted to operate in,” says Marshall. “They had to be sure that our wireless signals wouldn’t interfere with wireless signals already being sent in their offices for things like printer servers, Web connections, laptop networking, warehouse communications, and so on.”

Marshall says this application is significant not because the radio frequency technology is all that novel. Rather, it’s significant because it’s another sign that the manufacturing sector is willing to put this much faith in wireless.

“It’s a logical extension of the step taken not long ago as manufacturers went from proprietary communications networks that automation suppliers offered to the open Ethernet connectivity we see today,” says Marshall. “The fear that engineers once had where Ethernet is concerned has gone away. This customer’s step away from wired to wireless Ethernet is similar.”

Wireless makes washdown easier

Our third example of wireless technology applied in packaging is found at the new 130,000 sq ft facility of Norris Foodservices in Bohemia, NY. The firm makes and delivers sandwiches in a variety of package formats—some flexible, some rigid—to convenience stores in New York, New Jersey, and Pennsylvania. In this wireless application, a key consideration was sanitation.

“We wash down the facility every night,” says Michael Norris, one of the principals of the firm. “So the more wires I can move out of my facility, the easier that wash-down becomes. Wireless capability lets us eliminate the need for penetrations from the ceilings for data cabling drops that would have complicated our daily cleaning and sanitation efforts.”

Another advantage gained, says Norris, is that the operating parameters that need to be entered into the packaging machines each time a new item goes into production can now be downloaded from a single station.

“The packaging machines connected by wireless Ethernet are peers on a network,” says Nick Miceli of Atlantic Business Systems (631/582-1400), the information systems integrator that worked on the Norris implementation. “They can be addressed from an office laptop if you like. Before the arrival of wireless, you had to visit each machine with a laptop and download the new parameters.”

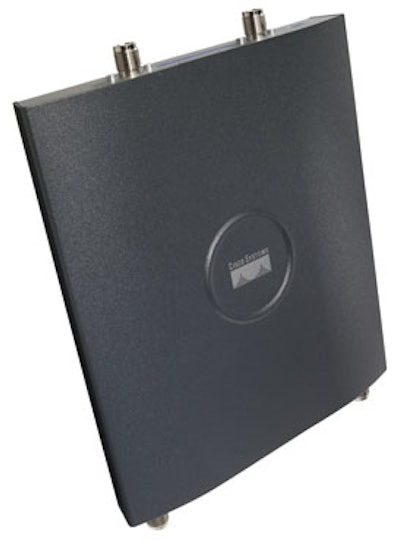

The packaging machines at Norris’s plant that have wireless capabilities include seven metal detectors from Lock Inspection (www.lockinspection.com) and 13 thermal-transfer print-and-apply labelers from Weber Marking (www.webermarking.com). Integrated into each of these is an 802.11g wireless Ethernet card that permits communication with the Local Area Network (LAN). Making that network accessible throughout the facility—manufacturing and office space alike—are Cisco (www.cisco.com) Aironet 1240 Series access points. Cisco also provided the 4400 Series wireless LAN controller that governs all 45 or 50 access points. Miceli says the network at Norris Foodservice is an example of a fairly recent development known as LWAPP (Light-Weight Access Point Protocol). He explains.

“Access points can contend with each other for band width. What Cisco and a few others have come up with instead is a centrally managed wireless infrastructure. Much of the intelligence that would ordinarily reside in the individual access points has been removed and resides instead in the LAN controller. It makes decisions about signal accessibility across the entire network, boosting power to access points that need it and reducing it to those that don’t. It reduces the chance for ‘coverage holes’ that can occur when access points act as free agents.”