As machine vision and inspection systems have evolved into faster, more affordable quality- control tools, they’ve become more and more common in the packaging operations of any number of manufacturers. A good example is Alltrista Consumer Products in Muncie, IN, a manufacturer of two-piece home canning closures under the Ball, Kerr, and Bernardin brands. The company uses the Model F160 camera vision sensor from Omron to inspect each lid as it is conveyed down the line so defective lids can be removed before they reach final packaging. The company installed the first eight of its now 18 vision systems in early 2002.

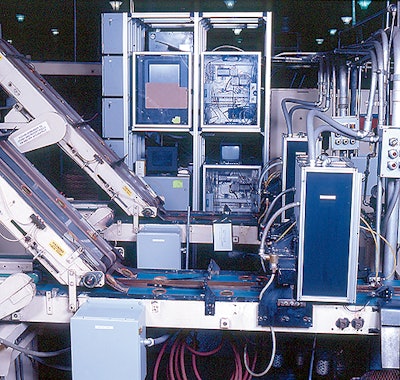

“We were using some older vision systems that employed late 80’s, early 90’s technology,” says Mike Dodson, senior process engineer with Alltrista’s Closure Manufacturing division. “The systems were bulky, becoming obsolete. They required large air conditioning units to cool the electronics. The air-conditioning units frequently went bad and were expensive to maintain. Also, those systems had slower processing times. That became an issue as our production rates increased.

“The Omron F160 offers a lot of functionality in a compact package. We were able to install two systems in the same enclosure that housed one of the old systems, which opened up some floor space and eliminated the need for the air-conditioning units completely. Because our product is not an extremely complicated design to inspect, we have the capability we need from the F160 system at a reasonable cost. A more costly, more complicated system would have been overkill for us.”

After exiting a curing oven, lids are transported to the final packaging area via conveyor, passing through Omron’s F160 system along the way at a speed of about 160 lids/min.

The F160 captures an image of the lid and sends that image to a PLC so it can be compared against defect limits that have been preprogrammed by Alltrista engineers and quality control personnel. After the PLC has determined the good/bad status of the lid, the result is stored and tracked until the lid reaches a reject station, where a signal from the PLC activates a reject mechanism that removes bad lids from the conveyor.

“The F160 menus are very simple to work with,” Dodson says. “We use the defects measurement tool primarily. It’s set upon different regions of the lid. I’m very impressed with the system. It even offers the capability for networking and data collection, which we have not tapped into yet, but will explore in the future.”

Code-reading camera

Also cashing in on the latest developments in machine vision technology is Transitions Lenses, a manufacturer of eyeglass lenses that turn darker when exposed to sunlight. In July, the Pinellas Park, FL, firm began running a new machine vision system that ensures accurate labeling on lens cartons. Old machine vision systems wouldn’t allow the company to automate its entire production line. The Cognex Insight 4001 high-resolution vision sensor reads 2-D code that tells an end-of-line carton labeler which lens is which.

“We’ve switched to a 2-D matrix etching on our lenses,” says Chris Rauscher, project engineer at Transitions Optical. “It’s kind of like a bar code, only it’s square and instead of having vertical lines it consists of a series of little dots. The benefit is that you can get a lot of digits in there from a very small mark called a data matrix. Other numeric vision systems sometimes confuse numbers. This new code should help us ensure that lenses are in the right cartons. The code also contains more information than we were able to include before.”

Information packed into the little code includes which eye the lens is designed for, strength of magnification, and color tint. The Cognex sensor, with a resolution of 1024x768 pixels, is housed in a closed cabinet. This resolution is very important because it allows the company to get an image of the entire lens for identification, not just a portion. The system runs at about 20 lenses/min.

A conveyor takes each lens into the closed sensor cabinet. The Cognex sensor, using software written by Rauscher that utilizes a pattern-finding tool to locate the 2-D code, is suspended at the top of the cabinet. A string of 12 digits is extracted and sent to a Rockwell Allen Bradley PLC. The PLC interprets the code and sends the information via network to a print-and-apply labeler.

The lenses exit the sensing cabinet and are moved into the cartoning machine. Cartons are then conveyed through the labeler, where they receive the proper identifying pressure-sensitive label from the print-and-apply labeling system.

While the system is still too new to tell how effective it’s been in guaranteeing that no lens winds up in the wrong carton, Rauscher says that’s not the primary reason Transitions made the change.

“It’s kind of a secondary objective,” he says. “The primary reason we’re doing this is because we want to automate other parts of our production process. With this new 2D code, we can now have all this information that tells us how to set up other machines in our process, and we’ll be able to automate all those from here.”

Printer inspection system

Not just packagers, but converters of packaging materials, too, are finding machine vision useful. Among them is Farnell Packaging Ltd. of Halifax, Nova Scotia. This Canadian manufacturer of flexible packaging and pressure-sensitive labels recently installed AVT’s PrintVision/Pro automatic inspection system and Automatic Bar Code Verification (ABCV) module to maximize productivity on its new Windmoeller & Hoelscher Novoflex® gearless flexo press. AVT’s pRegister automatic register presetting and control system has also been installed on the new 52”, eight-color press. The addition of the inspection systems is expected to enable the company to reduce costs, enhance its competitiveness, and solidify its current business.

“When we decided to bring in what we consider the ‘Cadillac’ of presses with the latest servo technology, we also wanted to have the quality control systems that can keep up with it during run time as well as the make-ready stage,” says Dan Christianson, vp of operations for Farnell Packaging.

AVT’s PrintVision/Pro system identifies defects by taking a digital master image of the print repeat at the start of a job. During the run, if the sensor detects a variation between the master image and what’s being printed, it alerts the operator, who can see the error displayed on the PrintVision console monitor.

The system works with any type of material, including paper, foils, and translucent or opaque films. It can detect color variations, splashes, misregistration, hazing, streaks, misprints, and spots. For Farnell, the vision system detects slight problems on polyethylene film that are invisible to the naked eye, indicating problematic trends that can worsen over time and result in waste.

The proprietary machine vision technology of the ABCV bar-code verification system automatically identifies and verifies all bar codes printed on the product, ensures their quality, and identifies and verifies all bar code quality parameters. Unlike a laser scanner, the ABCV doesn’t scan each bar code and report the findings to a screen where the operator can view and troubleshoot problems. The bar-code verification system takes a video-type image of each bar code and analyzes the image using AVT software to find a “grade.” If the determined grade is less than the acceptable pre-programmed number, a screen pops up on the operator’s data window.

“I know that AVT’s inspection systems are helping us to advance our production efficiency,” says Don Farnell, president and founder of the company. “On the new press, we have an increased ability to view all details and detect any defect occurrence. That’s extremely important with the very fine process printing we do for our customers.”

Farnell Packaging’s customers include those in Atlantic Canada’s fishing industry, as well as bakery and fruit and vegetable industries throughout Eastern Canada and the Northeastern United States. According to Christianson, the company has already lined up a number of new accounts to go into production on the new press.

Controlling quality

At Capalux, the St-Césaire, Quebec, Canada-based manufacturer of aluminum bottle caps, product is inspected by a pair of DVT SmartImage Legend 540 vision sensors. Installed last year, the sensors inspect printing on the top and side of the aluminum bottle cap.

“One camera is used to look at the top of the cap, the other is used to look at the side of the cap,” says Louis Allaire of ElectroSolutions, the systems integrator that helped install the DVT system. “On the top, we locate the logo and verify that it is not off center, and on the side we verify that there is something printed there.”

If the logo is more than 1.5 mm off, the cap is ejected with an air jet into a reject box. Running at speeds of 250 caps/min, production time is completely unaffected by cap defects, Allaire says.

According to Allaire, because of the new machine vision system, Capalux receives less complaints and product returned from the customers. The human operators previously inspecting the caps could only effectively inspect for about 30 minutes at a time.

“And even then,” he says, “it was very hard to concentrate on four caps per second. With the new system every cap is inspected all day long. And Capalux doesn’t have complaints from their clients anymore.”

After the caps are printed, they go through the DVT inspection station. The good caps then move on to additional manufacturing stations before they’re counted and boxed for shipment.

“There are 10 total lines, three of which are identical,” Allaire says. “The vision system is installed only on one. It’s sort of a prototype. But we have plans to integrate the inspection station on two additional lines within the year.”

For a list of suppliers mentioned in this article, see: packworld.com/go/w101

See sidebar to this article: Total inspection