Privately held organic yogurt producer Stonyfield Farm recently invested $2.5 million in new packaging equipment as part of an $11.5 million expansion/renovation project that's doubled capacity at the company's Londonderry, NH, headquarters facility.

Last December, two key new lines were the first to be up and running in a new packaging room. They are:

* Line 1, the plant's highest-volume line at four million cases/yr that fills 8-oz cups of yogurt at 260/min speeds, and

* Line 2, a multipack line that fills 4-oz cups of yogurt sold in six-packs (see sidebar, p. 36), at 240/min rates.

The company also runs three older lines. One packs 6- and 8-oz cups at 210/min, while another handles 32-oz cups at 100/min. Space also exists to add another new line. Presently, however, the company uses that space to semi-automatically fill yogurt into pails for foodservice accounts. Total plant capacity is now 200ꯠ cases/week, double what it had been.

Coordinating growth

"Consumer demand was rising quickly, and we planned for a national rollout of the multipack, so we had to be able to produce at a higher pace," recalls Mary Jo Viederman, the company's director of "cow-munications."

To coordinate its growth plans and manage operations, the company enlisted John Daigle. "He worked with General Mills' Yoplait Division," says Viederman. "There aren't many people with his experience in producing yogurt."

The expansion "has doubled the size of our filling and packaging area," says Daigle, vice president of operations. "Before we had three packaging lines, but were only able to run two at any one time due to our batch processing constraints. We were running 600-gallon batches. That meant we couldn't run very long before we'd have to make a changeover. That was time-consuming and complicated considering all the products we make."

During the batch-processing mode, Daigle says, "We were running approximately 100ꯠ cases per week, and it took seven-day-a-week production, with two daily packaging shifts and one daily sanitation shift. In that format, we weren't able to grow because we were already running as much as we could."

After carefully analyzing its processing and packaging functions, the company switched from batch to continuous processing. By doing that, Daigle says, "It freed us to run the third packaging line. We were able to run a more concentrated schedule, five days a week, and use the weekends for plant construction and other tasks."

Standardized machinery

While the processing change represented a major step forward, the two new lines enabled Stonyfield Farm to meet rising sales demands. Daigle's previous experience helped guide him in the company's search for the equipment it needed to build capacity. All of the equipment was purchased with standardization in mind (see Packaging World, Oct. '99, p. 91, or packworld.com/go/standardization).

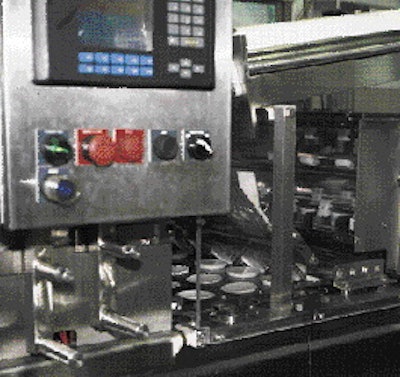

The key machinery on each of the new lines comes from Modern Packaging (Deer Park, NY). Both are high-speed, automatic yogurt filling lines with clean-in-place systems.

The machine used on Line 1 is designated an MP 358: SL 2x6. It fills 8 oz of yogurt into each of 12 plastic cups, configured in a 2x6 pattern, heat-seals plastic lidstock to the cups, then applies a plastic overcap to each cup.

Positive-pressure HEPA air filters are used in the fill area to screen out unwanted microorganisms, particulates and bacteria where the yogurt is filled into the cup. On Lines 1 through 4, the HEPA filtration system rests on top of a plexiglass cabinet that encloses the filling area. For the two new lines, this cabinet measures approximately 4'Wx8'Lx6'H.

Daigle believes controlling the immediate filling environment is effective, because the only time the product is exposed to the environment is during the short span between filling and lidding. Controlling the fill environment is also easier than transforming the entire packaging room into a clean room. The HEPA-filtered air systems were purchased new for Lines 1 and 2, while Lines 3 and 4 were retrofitted with the HEPA-filtered air.

Cup filling

At the beginning of Line 1, a magazine holds nested polypropylene cups that are injection-molded by Polytainers (Toronto, Ontario, Canada). Cups are automatically dispensed from the magazine into an indexing conveyor and held in place by vacuum. The servo-driven machine uses a switching block to draw yogurt from a filler bowl during a suction stroke. Then, during a discharge stroke, the machine fills the appropriate amount of yogurt into each cup.

The conveyor indexes the 2x6 configuration of filled yogurt cups to the lidding station. This station accommodates two film rolls so that changeover can be made quickly from one roll to the next. The film, identified only as a lamination that includes PP, unwinds downward and is heat-sealed onto the filled cups. A serrated knife system cuts the material around the lip of each cup before the skeletal web is rewound. The use of all-plastic lidding permits Stonyfield to employ a metal detector on the line.

"I'm not aware of any of our competitors doing this," says Daigle. Viederman adds, "Because we do not use aluminum foil, we are able to thoroughly check our product for metal-based foreign bodies."

Before cups reach the metal detector, however, the Modern Packaging machine applies an injection-molded linear low-density polyethylene overcap, also from Polytainers. Once overcapped, cups discharge from the machine on a conveyor where they proceed through the detector from Goring Kerr (Westmont, IL).

Accumulating benefits

From the metal detector, cups proceed past the printhead of a Markem (Keene, NH) ink-jet coder that prints a date code onto the overcap's skirt. "The Markem equipment is used on Lines one, two and three," notes Viederman. "They've proven to be reliable, and we feel they are state-of-the-art equipment."

Coded cups are then conveyed through a bi-directional accumulating conveyor that includes a plexiglass top. It's supplied by Garvey (Blue Anchor, NJ). "The Garvey system is something I used at another plant that worked well," recalls Daigle. "It not only moves the cups from one point to another, but it provides us with about four minutes worth of accumulation, at a line speed of 260 cups per minute."

He explains that because the upstream filler continually supplies cups, if there is a jam or back-up at the downstream case packer, the Garvey unit can convey those filled cups to prevent excessive back-ups at the case packer. As cups exit the Garvey unit, they move past dividers that separate them into four lanes for downstream case packing.

Case venting

From the Garvey machine, cups move into an older case packer that Stonyfield Farm had rebuilt by an outside vendor. The packer erects cases and packs twelve 8-oz cups/case. These 175#-test, B-flute vented corrugated cases come from Smurfit-Stone Container (Chicago, IL). They're clay-coated and printed in two colors.

As is common to yogurt processing/packaging, the vented cases serve an important purpose. Daigle explains: "The yogurt is warm, and we want to keep it that way so that the active cultures in the product can grow." Cases are manually stacked onto pallets and moved into a warm "incubation" room for three to five hours. During this time, active cultures in the product break down the milk proteins and produce lactic acid. The process turns the liquid milk into the consistency of yogurt.

"Pallet height is very important for yogurt," Daigle notes, "because after we incubate it, it has to be chilled. The specific height and width of the pallet have to be carefully considered in order to achieve the best flow of air in cooling the temperature-sensitive product.

"We spent a lot of time working with Smurfit-Stone to develop the whole concept of air flow so that we can keep the product warm, and then be able to cool it down quickly when we need to stop the growth of the active cultures," he says.

Stretch wrapping of cases isn't done until the product is ready for shipping. Product is picked to meet specific orders. Stonyfield Farm relies on common carrier and its own fleet of trucks, all of which are refrigerated. Yogurts are sold through the refrigerated chain, with a shelf life of 50 days from the date of packaging.

Future plans

Daigle says that automated palletizing is likely in Stonyfield's future. At the time of PW's plant visit, he anticipated adding one machine to handle the output of four filling lines. "We have to have equipment that's able to handle five to 10 changeovers per day on each line," he says. "The palletizer needs to be ready to accept different sizes of loads from any of the four lanes."

Daigle would also like to see the line produce a mixed pack. "The design of the line was built around the concept of a club-store pack. My vision was to be able to put one flavor on one side [of the 2x6 configuration] and another flavor on the other side so we could pack two flavors in a case." While a mixed pack for 8-oz cups isn't on the market now, Stonyfield Farm does market two flavors in its "Planet Protectors" six-pack of 4-oz cups.

For now, however, Daigle is pleased with the plant's additional capacity. "We run the new lines two shifts per day, five days a week," he notes. "This was a growth-oriented project that's allowed us to yield greater throughput with the same number of people, or less.

"We were looking to double our volume, so we had to make an investment in packaging equipment," he summarizes. Noting his previous experience, Daigle believes "the capital investments we've made were less expensive than [expenditures] made by our competitors." He says Stonyfield Farm's return on investment for the equipment on the two new lines is 30 months or less, depending on the machine.