The device senses the diameter of the expiring roll of film and automatically splices the end of each expiring roll onto the new roll. It is capable of running at speeds of up to 600 ft./min. (FPM). In eliminating film roll change and manual splicing, Butler’s automatic splicing technology typically reduces downtime by 5-10 min./operational hr. For a typical packaging line operating 20 hr./day, 6 days/wk., this can yield up to 20-25 hours of additional production per week, or the equivalent of an extra day’s production.

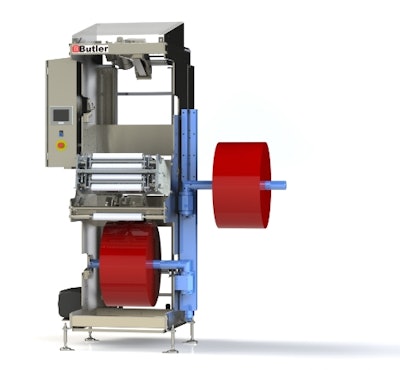

With a simple mechanical design and high-quality manufacture, the SP1 promises long-term, trouble-free performance.

In addition to the standard SP1 automatic splicer, Butler offers the SP1 RB, designed for full wash-down capability. The SP1 RB is built to standards common with many regulatory requirements. It features mostly stainless steel construction, with only specific splicing head cylinders using coated aluminum, and has minimal flat surfaces.