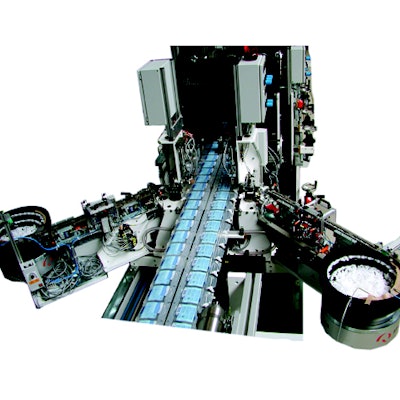

Bags with spouts and tubes (KGA), bags with press-to-close zip

closures, and spouts with screw closures can be manufactured in a wide

range of formats. Previously, these bags were produced in two

manufacturing stages in a bag-sealing machine and a spout-welding

machine. B&B-MAF’s in-line production offers cost benefits as a

result of reduced machine staff, a lower overall reject rate, and a

higher machine output of up to 250 pouches/min. The machine costs

compared with two individual machines are also lower. The machine has

the ability to integrate to filling equipment.

Companies in this product