The existence of recyclable packaging components does not guarantee that they make it into the proper recycling streams. This is especially the case when the lid and tray of a medical packaging system must be recycled in two different streams.

Kyle Vafiadis, technical service engineer at Tekni-Plex, Inc., discussed challenges and considerations for creating recyclable medical packaging in a demo at PACK EXPO Connects.

Materials

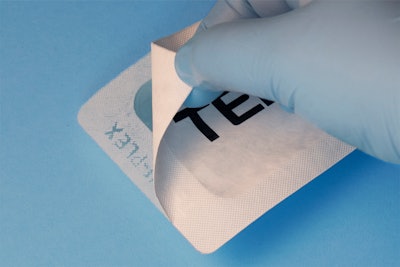

DuPont Tyvek, manufactured from HDPE resin, is a breathable film amenable to many types of sterilization methods. It is recyclable in existing PE medical waste streams, and when mated to a PE medical tray, the entire package can be sent into the same PE recycling stream.

Vafiadis said that while the Healthcare Plastics Recycling Council (HPRC) identifies Tyvek as a material desirable for recycling, mixed waste streams present a collection challenge per an HPRC study:

"DuPont Tyvek was found to be most difficult to collect because it mimics paper and clinicians had to fully separate a Tyvek lid from the bottom container to meet the recycler’s acceptance criteria. The hospital's key takeaway was that an effective clinical program must (1) be simple for clinicians to follow and (2) reduce the sorting burden at the point of collection” (per the from the Chicago Regional Demonstration Project Report presented by HPRC and PLASTICS, December 2016).

High density polyethylene (HDPE) can be used in either flexible or rigid forming webs and is a well-established polymer in the marketplace. “It utilizes the same polymer as Tyvek, simplifying the potential waste stream. HDPE is a #2, miscible with LDPE #4 four waste allowing it more versatility for post-consumer recycling,” said Vafiadis. HDPE has good inherent moisture barrier and can incorporate additional barrier and functional layers such as EVOH, some of which are preferred by the Association of Plastic Recyclers (APR).

End user challenges with recycling medical packaging

“For the end user, a proliferation of material types making up waste components makes collection difficult,” he said.

For example, a 35 mil PX medical tray and a 52 pound paper lid are both recyclable, but would require two waste collection containers and processing methods.

“For the combination to be viably recycled, they would need to be collected separately by the consumer and sent to a recycler that could process both wastes or alternatively sent to a recycler that could sort and process both of these materials onsite,” noted Vafiadis.

One recycling stream

An HDPE tray with a Tyvek lid, on the other hand, would be collected in the same waste receptacle and processed by the recycler in the same waste stream— without sorting—in a #2 waste stream.

Vafiadis concluded that DuPont Tyvek and HDPE tray combinations represent an iterative step in the direction of more efficient recyclable waste streams.

And how does the adhesive on the Tyvek impact its ability for be recycled? Vafiadis noted that most adhesive components would fit into a #2 or a #4 stream, so they would fall into the category of converging waste streams. For the ones that don't, research has shown that the amounts of adhesive material present by the time they're applied and dried on the webs is well below most thresholds of concern for recycling additives.

Next steps

- Recyclability must be reviewed in preliminary design stages for proper material selection.

- Consumers and buyers interested in recycling should evaluate current top and bottom webs for opportunities to converge waste streams. Paper, which has its own waste stream and is not miscible with others, accounts for approximately 22% of waste collected per one study.

- Current recycling infrastructure needs investment in volume to make recycling of flexible webs more enticing. Converters and raw material suppliers should collaborate to find outlets for higher volume streams to entice investment in advanced recycling technologies.

To view the demo in its entirety (available through March 31, 2021), and add Tekni-Plex Inc. to your MyConnects Planner, click here.