Opportunities for using smart machines to address the packaging industry’s top challenges – from higher SKU counts to cybersecurity – was a reoccurring theme earlier this month at PACK EXPO International in Chicago.

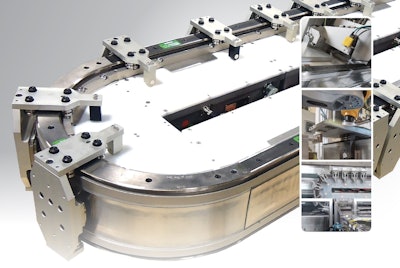

Attendees learned how smart packaging machines can create more flexible operations to support shorter production runs and a wider range of products. For example, the iTRAK system with independent cart technology from Rockwell Automation uses simple software profiles in place of traditional mechanics. This allows for fast, no-tool changeovers that can occur with just the press of a button. The ability to easily reconfigure the system based on the package being run can also optimize a machine’s performance.

Attendees also saw and heard about advances in industrial IoT applications that can help boost productivity, improve uptime and reduce risk. One of those advances is scalable analytics,which structures and contextualizes data at the device, machine and enterprise levels. These analytics can leverage workers’ knowledge of a machine or process and be aligned to specific business outcomes.

“OEMs can use machine analytics to increase visibility into their machines and offer new services to customers,” said Steve Mulder, OEM packaging and segment leader, Rockwell Automation. “For example, machine diagnostics can help end users proactively schedule repairs and avoid downtime. And work instructions delivered in an augmented-reality experience can improve repair times and accuracy. Remote monitoring can even allow a manufacturer to hand over certain maintenance tasks to their OEM partner.”

Presentations at PACK EXPO International also focused on how attendees can secure their connected packaging operations. Rockwell Automation discussed best practices and actionable steps that companies can take in accordance with the ISA/IEC 62443 standards and the NIST Cybersecurity Framework.

One resource for machine builders and end users are the Converged Plantwide Ethernet (CPwE) design guides. The documents, developed by Rockwell Automation and Cisco, provide design guidance and best practices for creating scalable, robust, safe and secure network architectures. Rockwell Automation also provides industrial security services to help companies protect their assets, data and workers.

More information about creating productive and flexible smart machines is available in the packaging trends eBook from Rockwell Automation.