High-volume, food manufacturing lines thrive on standardization to pull through operational efficiencies, be it control architectures, processing systems or supply chains. Managing multiple plant standardization within an enterprise has been a great challenge for the last twenty years in the food and beverage industry, often due to integrating acquired companies.

For the food and beverage industry, identifying the source of downtime on fast-moving packaging or production lines can be difficult. However, advances in industrial networking technologies and cloud solutions are now enabling companies to be nimble and targeted with improvements for operational efficiencies.

In 2016, Chicago-based Sage Clarity introduced its Auto-tagging Business Logic Engine (ABLE) application that performs root-cause analysis via cloud-based modeling of machine centers for many types of manufacturing applications, including food and beverage. The solution, coupled with OPC-UA technology via Kepware ServerEX and its custom interface drivers, forms an industrial IoT solution for high-volume production lines that can automatically identify the source of downtime.

“If a company has 30 plants, they can essentially look at all their plants’ configurations and modify them from a centralized repository—the cloud,” says John Oskin, president and CEO of Sage Clarity.

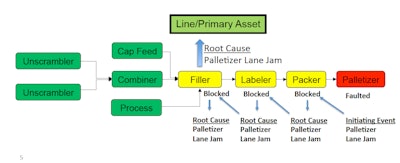

In a recent presentation, Sage Clarity demonstrated how the cloud-based modeling works for packaging lines, with either simple or complex line flows. The modeling targets individual machine centers on production lines and creates a series of “condition” elements that each represent a state and reason; optionally linking to a root cause.

The conditional elements can include state, local reason, logic and root cause link. For example, under logic, a boolean expression derived from a PLC/OPC tag determines if the condition is active or inactive.

The application can be used for dual-filler operations, complicated conveyor systems and scenarios where products converge or diverge as they move down the production line.

The logic engine tool resides between the OPC level and the MES /SCADA layer, and requires no PLC data acquisition programming. For new lines, the plant line cloud solution can be modeled and configured before commissioning, according to Sage Clarity. The cloud-based tool can also be used for existing production lines.

Oskin cites how PLCs have evolved into data acquisition tools to feed historians, MES systems or enterprise resource planning software. However, this tool eliminates the need for a PLC data concentrator that receives individual machine control signals and aggregates them back to a central PLC, according to Sage Clarity.

“With an OPC and cloud-based configuration solution, you don’t need a concentrator PLC,” says Oskin. The solution can connect to each PLC on the line directly and correlate the data across PLCs and can takes the PLC back to its roots.”

Removing data storage and data transformations from PLCs allows enterprises to treat the PLC as an IoT device, simplifying their control architectures, according to Sage Clarity.

Oskin adds customers are enjoying the benefits of better root-cause analysis of their production lines but also improved data fidelity with better tagging of information. The analysis provides Pareto charts that identify root cause, reduces integration cost for auto-tagging by 50 percent, and can reduce PLC programming for auto-tagging by more than 80 percent, according to Sage Clarity.