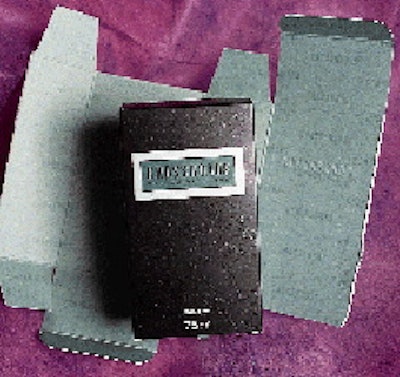

Narrow-web flexographic printing for cosmetics folding cartons? Even just a few years ago, it would have been unthinkable to most cosmetics companies. However, Amway Corp., Ada, MI, believed that state-of-the-art flexo printing and UV curing had come very close to the quality of offset printing. So Amway bought a narrow-web flexo press from Arpeco Eng. Ltd. (Mississauga, Ontario, Canada) to print cosmetics folding cartons in-house, rather than continuing to rely on outside vendors. The press was part of a $17 million expansion of Amway's captive printing operation. The 10-station narrow-web press, running since mid-1996, has slashed carton ordering times from 12 to just two weeks. And though Amway wouldn't disclose annual cost savings figures gained by decorating in-house, return on investment for the press was said to be just 12 months. The cartons printed on the press hold containers of premium-quality skin cremes, makeups and perfumes that sell for anywhere from $4 to $48. The products do not appear in retail stores; rather, they're sold worldwide through a network of beauty consultants. The reduced lead time permits Amway's cosmetics division to order folding cartons every four weeks versus every 20 weeks, as was previously required with outside vendors. That reduces excess carton inventory and eliminates the potential of waste due to inaccurate forecasting of product demand. "Rather than the cosmetics group having to forecast several months ahead, our shop can turn on a dime," says narrow web team member Tom Plett. "In six hours we can produce cartons for them if necessary." All processes in-line Of course, the argument for flexo is the efficiency of the process. While offset printing used previously permitted higher speeds, carton stock had to travel through no less than five operations requiring seven people at Amway's vendor. Today, all five steps are done in-line on the Arpeco press with three people. Amway runs the press at about 180'/min, though it has run it as fast as 220'/min. A final benefit of the press is that it permits Amway to conduct R&D work right on the press. "For example," says Plett, "we've worked with the artists and marketers in developing some new cartons with new technologies, including raised-surface varnishes, special embossing techniques and metallic inks." The press starts out with a 60" OD roll of 12"- to 16"-W cosmetic carton board from the Finnish paper company Metso/oo-Serla Corp., sourced through Schwartz Paper Co. (Morton Grove, IL). Amway uses thicknesses from 12 to 22 pts. Designed expressly for high-end applications, the board has a very smooth, bright white finish. During Packaging World's visit, the Arpeco press was printing one of Amway's Artistry cartons for an overseas market. After unwinding, the board passes through a series of idler rollers, followed by a web guide and web cleaner. Then it enters the first print station, which prints a repeating design on what will become the interior surface of the carton, followed by UV curing. The web then passes through the next station, a flood-coating tower that applies a clear coating over the interior printing. This coating is designed primarily to prevent scuffing of the primary package or the label on the bottle inside the folding carton. At each print station, UV lights immediately "cure" or dry the inks before the material reaches the next station. Next, the web is flipped over on a turn bar, and the front side passes through eight more stations where it is printed and gloss-coated. Some cartons receive a clear coating that gives the surface a raised, textured feel. Embossing in-line The web then passes through the rotary embossing station, which produces the fine, embossed detail found on cartons for Amway's Artistry line of cosmetics. At the embossing station, the web passes between two cylinders, one of which is engraved with the desired pattern. According to Plett, it was difficult to find a flexo press that could emboss in-line. Simpler spot embossing, like that used on the black Crossroads carton, is actually done in the next station, the die-cutter. The die-cutter is a flat-bed-style unit, not rotary, that separates the individual carton blanks from the web. At the moment the web is cut, it's halted while a rocker arm takes up the slack. Finished, die-cut carton blanks emerge from the press in a continuous shingle feed. An operator stacks the blanks, which are then taken to a folder/gluer. Changeover is fast, according to Plett. Size and plate changeover-where everything is changed but the inks-takes about an hour. Print runs last anywhere from 15 min to 6 hr. A final benefit of the press is its ability to automatically adjust on the fly to stay in register, tracking a registration line that's printed in the margin of the web. That the flexo press is being used for a high-end cosmetics carton application is a strong Amway vote of confidence in the quality of flexo. "We got the press [solely] to do our fine cosmetics cartons," says Plett. But how does Amway view the print quality in a head-to-head comparison with offset? "Dot for dot, offset [would be preferred]," admits Plett, "but with this press, flexography is gaining by leaps and bounds. I'd say it's neck-and-neck right now with offset, or at least very close."